Grain Storage Solution

Your Challenge

Grain storage and conveyance systems operate in severe environments: high dust, moisture, constant heavy loads, and abrasive grain materials. Equipment failure not only leads to costly repairs but can also cause you to miss critical harvesting and shipping windows.

Our Solution

We supply Engineering-Class Sprockets, Chains, and Heavy-Duty Bearing Units specifically tailored for agricultural and grain handling applications. We ensure your bucket elevators, drag conveyors, and reclaim systems achieve the highest reliability and lowest downtime.

Power Transmission Parts For Grain Storage System

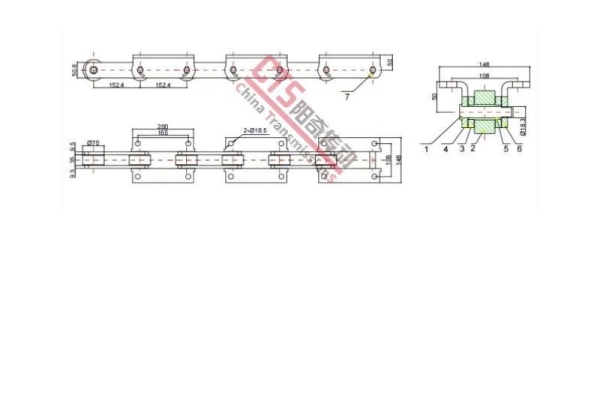

• Double Pitch Conveyor Chains are often used in horizontal conveyors that move grain over long distances at lower speeds, such as moving grain from a dryer back to a storage bin.

• Drop Forged Link Chain (Scraper Chain): Used in the conveyors running along the top of the grain bins. These chains carry the grain from the central elevator and drop it into specific silos.

• Welded Steel Chain (WH/WR Series) is used at the very beginning of the process. When trucks dump grain into the receiving pit, welded steel chains move massive volumes of grain toward the elevators.

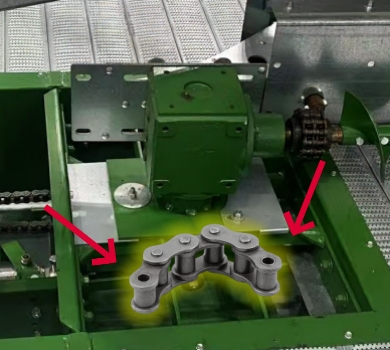

• Heavy-duty roller chains are usually used for grain lifting, which involves constant "stop-and-go" stress. Our chains are designed to resist fatigue, meaning they won't stretch or snap even after thousands of hours of use.

CTS Transmission Chains: Built for the Grain Environment:

- Wear-Resistant Materials & Heat Treatment:

All engineering-grade sprockets use 1045 Carbon Steel or higher-spec alloys, subjected to precise induction or flame hardening to ensure tooth surface hardness reaches HRC 45+ - Precision Manufacturing:

Strict control over chain pitch tolerance and sprocket tooth profile accuracy ensures optimal meshing, reducing wear by up to 20%. - Corrosion Resistance Options:

We offer galvanized or stainless steel chains suitable for high-humidity or wet grain handling environments. - Various Chain Attachments:

Chain attachments such as bent plates, extended pins, and scraper flights can be bolted or welded onto base chains to perform functions including pushing, scraping, lifting, or conveying bulk grain.

Professional Note: According to grain industry standards, using hardened sprockets and sealed bearing units can extend equipment life by up to 40% in high-dust environments.

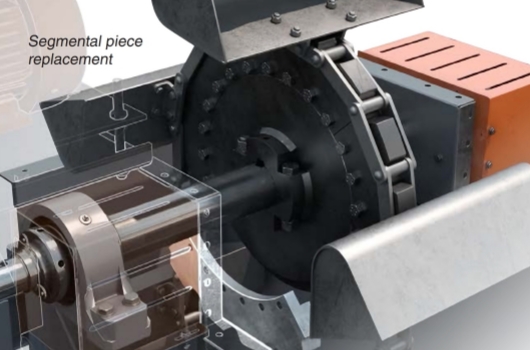

• Sprockets engage with all the chains mentioned above to provide movement. Split Sprockets are especially popular on the "Head Shaft" (the top) of bucket elevators.

Our sprockets feature hardened teeth to resist the "sandpaper effect" of grain dust. Split sprockets allow maintenance teams to replace them without dismantling the entire conveyor shaft.

• You will find bearing units at every end-point of a conveyor or elevator. They support the shafts that hold the sprockets and pulleys.

In grain facilities, sealing is everything. Our bearing units use triple-lip seals to keep out fine grain dust. This prevents the bearing from "seizing" (locking up), which could otherwise cause a fire in a dusty silo.

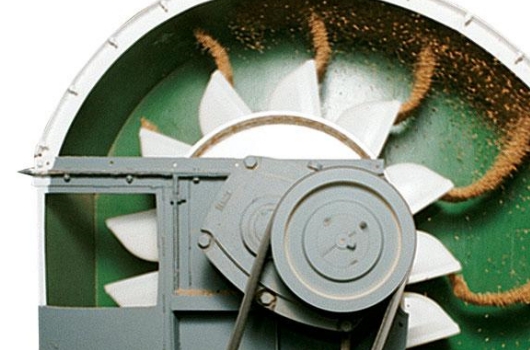

• High-speed Aeration Fans (used to cool grain in bins) and Dryer Blowers almost always use V-belt drives. The pulley sits on the motor and the fan shaft.

V-belts can handle high speeds and provide a "safety slip."

OEM

Custom Solutions

Standard chains and sprockets may not always meet the specific requirements of grain storage applications. Different grain types, conveying distances, loads, and environmental conditions often demand custom-engineered chain, sprocket, and bearing solutions. Our engineering team can customize parts to match your existing system dimensions.

Ready to upgrade your grain storage system?

As an experienced industrial chain and sprocket manufacturer, we offer fully customized solutions to match your grain storage system.

Contact nowApplication Area

CTS Industry Application

Provide a more efficient and reliable automation chain for the food and beverage industry

Provide a more efficient and reliable automation chain for the agricultural machinery industry

Provide a more efficient and reliable automation chain for the packaging and logistics industry

Provide a more efficient and reliable automation chain for the palm oil industry

Provide a more efficient and reliable automation chain for the wood processing industry

Provide a more efficient and reliable automation chain for the lifting industry

Help you succeed

Affordable and full of potential in the future

Areas such as Industry 4.0, digitalization and automation have always been key topics in industry development. We turn your challenges into our shared opportunities. Ideally located, we are able to respond flexibly to changing needs and continually drive the development of new products to meet the requirements of highly automated systems. In this process, we always put economy and efficiency first.

Therefore, we keep a close eye on production costs throughout the project. Through sophisticated calculations of total cost of ownership (TCO), we demonstrate optimization potential and concrete solutions for cost savings. We are committed to providing you with more affordable solutions that will help you thrive in the future.

Ask The Experts

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.