Quality Control for Industrial Transmission Products

Comprehensive quality control process to ensure excellent quality every step of the way

Comprehensive quality control process to ensure excellent quality every step of the way

Total Quality Control Process

By strictly controlling every step, we are committed to improving product reliability and performance.

1. Material Selection and Inspection

Before production starts, we select high-quality raw materials and conduct strict material inspections. This ensures that the starting quality of each sprocket chain is of the highest standard.

2. Manufacturing Process Monitoring

We implement strict manufacturing process monitoring and use advanced production equipment and real-time monitoring systems to ensure that every step is carried out in accordance with design specifications and process flow. Any deviations are immediately detected and adjusted promptly.

3. Dimensional Accuracy Control

Through high-precision measuring tools and automated control systems, we accurately measure and control the size of each sprocket chain. This ensures that each component meets the dimensional accuracy required by the design.

4. Functional Testing

After manufacturing, we conduct comprehensive functional testing to ensure that the sprocket chain will achieve optimal performance in the actual application. This includes aspects such as wear resistance, load-bearing capacity, and stability of axial and radial movements.

5. Quality Inspection Link

We have set up a special quality inspection link, and our experienced quality inspection team conducts the final inspection on each sprocket chain. Full compliance with quality standards is ensured through visual inspection, functional testing, and dimensional measurements.

6. Packaging and Factory Inspection

Before leaving the factory, we do the final packaging and inspection. The packaging is designed to ensure that the product is not damaged during transportation and storage. Factory inspection is the last step to ensure that the products received by customers are high-quality products that have been fully inspected.

Our Commitment to Quality

Continuous Improvement

We are not only satisfied with meeting current quality standards, but also committed to continuous improvement. We continuously improve our quality levels through customer feedback, internal reviews and technological innovation.

Transparent Communication

We maintain transparent communication with our customers and provide detailed quality reports and performance data. We believe transparency is the foundation for building trust.

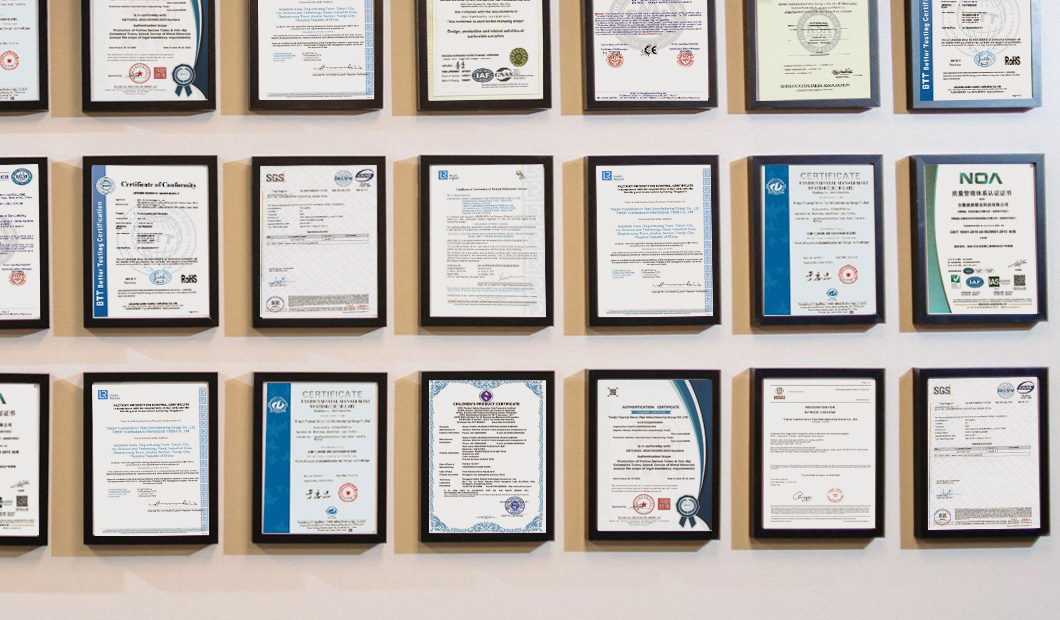

Quality Assurance

Our products undergo multiple inspections and tests to ensure they meet the highest quality standards. We have a strong guarantee on the quality of each sprocket chain.