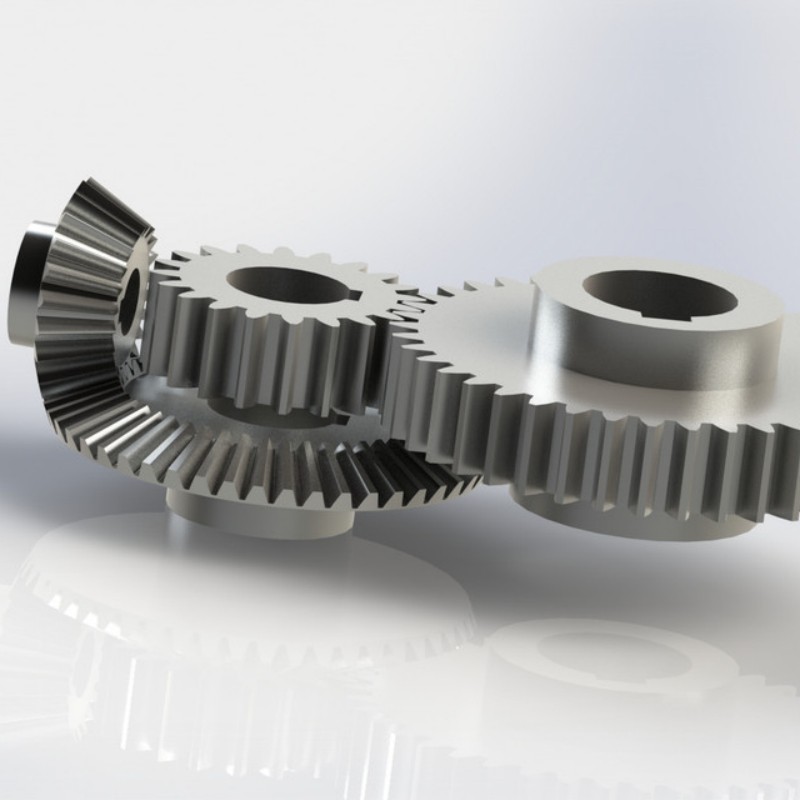

What Is Spur Gear?

Spur gears are the most commonly used gears, featuring straight teeth and mounted on two or more parallel shafts. The design of the spur gear is simple. Spur gears are also referred to as low-speed gears because of the noise at high speeds.

There are three important types of track gears: External Spur Gear, Internal Spur Gear, and Spur Rack and Pinion.

Spur Gear Type

External Spur Gear

These spur gears have external teeth on the outer surface of the cylinder. When the two gears are engaged, they two gears will rotate in opposite directions. The drive is generally smaller in size, and the drive moves in the opposite direction to the drive.

Internal Spur Gear

In an internal spur gear, the teeth are cut on the inner/inner surface. This gear will go into that pinion like a ring, or smaller gears will mesh inside it & both shafts will rotate in the same direction.

Spur Gear Rack and Pinion

It is a special type in which the nodal plane is a plane, meaning that it has an infinite diameter, which is called a rack. It also has identical teeth of the same modulus as the usually smaller pinion.

Metric VS. Imperial Spur Gear

| Feature | ||

| Measurement System | Module (M) | Diametral Pitch (DP) |

| Spur Gear Size | Module 2, Module 3, Module 4...... | 16DP, 20DP, 24DP...... |

Spur Gear VS. Helical Spur Gear

Straight Spur Gear

Helical Spur Gear

| Feature | Straight Spur Gear | Helical Spur Gear |

| Tooth Shape | Straight | Angled |

| Noise Level | Higher at high speeds | Quieter due to gradual engagement |

Load Capacity | Lower | Higher(greater contact ratio) |

Application | Low-to-medium speed, parallel shafts | High-speed, heavy-load, quieter operations |

Advantages and Limitations of Spur Gear

Advantages of Spur Gear

Simple design and cost-effective

High efficiency

Easy installation and maintenance

No axial thrust

Limitations of Spur Gear

Nosiy at high speed

Limited load capacity compare to helical spur gears

Only suitable for parallel shafts arrangements

Application of Spur Gear

Spur gears are widely used in:

Gearboxes and reducers

Electric motors

Automotive transmissions

Printing and packaging machines

Rack and pinion system for linear motion

Whether you need metric spur gears, imperial spur gears, or spur gear racks, they are widely available for different industries.

Still not sure about the best type of gear to use for your next project? Ask an expert!

With years of experience, CTS-ChinaTransmissionS has extensive engineering and manufacturing capabilities to provide unique solutions to your spur gear manufacturing problems. We specialize in precision gear manufacturing with strict quality control and can provide both standard and customized solutions.

FAQs

What is the main difference between spur gear and helical gear?

Spur gears have straight teeth and no axial thrust, while helical gears have angled teeth, generate axial thrust, and run more quietly.

How do I choose between a spur gear and a helical gear?

If your application requires low noise and higher load capacity,choose helical gears.If you prefer a simpler,cost-effective design with no axial thrust, spur gears are a better choice.