Industrial Transmission Chain

- Double vs. Single Roller Chain: Which is Better?Jan 7,2026Know the differences between single and double roller chains, and choose the right roller chain for your industrial application.

- Split Sprockets: The Secret to Reducing Harvest Downtime from Hours to MinutesDec 24,2025Reduce harvest downtime! Discover why split sprockets are the ultimate upgrade for grain silos.

- When to Use Welded Steel vs. Drop Forged in Your SiloDec 19,2025When to use Welded Steel vs. Drop Forged chains in grain storage and handling systems.

- Corn Head Gathering Chains & Sprockets: Factory-Direct Replacement SolutionsDec 11,2025Discover high-durability, factory-direct CA-Type agricultural chains (CA620) and sprockets for your John Deere 708C (and 700 Series) Corn Heads. Exact OEM fitment for Gathering Chains (AXE62423) and Auger Drive Roller Chains.

- CA-type Steel Chain VS. Other Agri Chains: A Quick GuideDec 3,2025This guide compares CA-type chains with other agricultural chains and provides selection advice, and FAQs—all in an easy-to-use format.

- How to select, maintain, and extend life of baking chainsNov 28,2025This guide walks you through the tunnel oven chains and sprockets—from selection, materials, maintenance, and life extension strategies.

- Types of Conveyor Chains Used in Wood Processing IndustryNov 10,2025Discover the different types of conveyor chains used in the wood processing industry, including pintle chains, welded steel chains, drag chains, and more.

- Metric Roller Chain Size Chart | Dimension GuideNov 3,2025Know the metric roller chain size chart with detailed dimensions, and the difference from ANSI roller chains. Select the right metric roller chain for your machinery and application.

- Choosing the Right Roller Chain MaterialOct 20,2025Discover different roller chain materials such as carbon steel, alloy steel, stainless steel, and nickel-plated steel. Learn how to choose the best roller chain for your industrial application based on strength, wear resistance, and corrosion protection.

- ANSI Roller Chain Size Chart | Dimension GuideSep 26,2025Explore the complete ANSI roller chain size chart with detailed dimensions, pitch, roller diameter, tensile strength, and weight per meter. Find the right ANSI roller chain size for your machinery and application.

- Innovation Design and Manufacturing Solution For Conveyor Chain SprocketsSep 19,2025Learn how conveyor chain sprockets are engineered with innovative design solutions, encompassing tooth profiles, material selection, heat treatment, and surface finishing, to ensure durability, precision, and efficiency in conveyor systems.

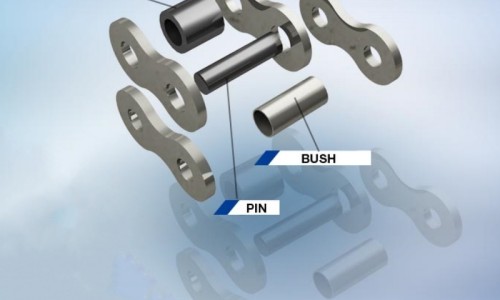

- Parts of Roller Chains | Structure, Function & ManufacturingSep 12,2025Learn the key parts of roller chains, their functions, and the manufacturing process. CTS offers expert insights and quality roller chain solutions.

Ask CTS?

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.

- China's professional power transmission manufacturer

- We offer customized product services and free samples to meet our customers' needs.

- Some of our products are mass-produced and kept in stock, ready for immediate shipment.

- Contact CTS

- Name