Technical Improvement for Industrial Transmission Products

Technological innovation leads the peak of sprocket chain performance

High-tensile & Wear-resistant Roller Chain

High-performance Material

- Chain Plate: 45Mn

- Chain Pin: 20CrMnMo

- Chain Bushing: 20Mn

- Superior roller chain materials ensure a longer service life.

Nitro-Carburizing Compound Heat Treating

CTS uses automatic heat treatment, which is more efficient and accurate. During the carbonitriding heat treatment process, the addition of ammonia significantly enhances the roller chains' durability and resistance.

Wide-waist Link Plates

Increasing in width of the waist, wider-than-standard waist link plates greatly increase chain fatigue resistance and shock-load resistance.

Application of Latest CTS Technology

By strictly controlling every step, we are committed to improving product reliability and performance.

CAD Design and Simulation

We use the most advanced computer-aided design (CAD) and simulation technology to analyze the design of the sprocket chain through precise mathematical models, optimize the structure, and improve performance. This ensures that products have excellent performance potential right from the design stage.

Materials Technology Applications:

By introducing new materials and heat treatment technologies, we continue to improve the wear resistance, corrosion resistance and load-bearing capacity of sprocket chains. Advanced material technology allows products to perform well under a variety of extreme working conditions.

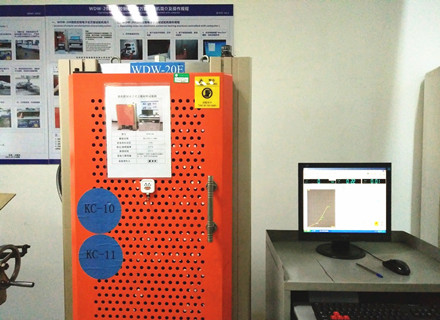

Dimensional Accuracy Control

Through high-precision measuring tools and automated control systems, we accurately measure and control the size of each sprocket chain. This ensures that each component meets the dimensional accuracy required by the design.

Technological Innovation Cases

Case 1

CAD Design and Simulation Optimization

We used CAD design and simulation technology to successfully optimize the gear structure of the sprocket chain. Through accurate mathematical models, we improved the shape of the gear, reduced friction loss, and improved transmission efficiency. Customers reported that the noise of the sprocket chain is significantly reduced and the performance is more stable when running at high speed.

Case 2

Material Technology Upgrade

Selecting the right materials is crucial for producing durable roller chains and sprockets. In the past, standard carbon steel was commonly used. We’ve now upgraded to advanced alloy steel and stainless steel materials, which offer improved hardness, corrosion resistance, and a longer lifespan. We also apply controlled heat treatment processes like carburizing and induction hardening to improve strength and surface hardness. These material upgrades mean our chains can handle higher loads and work longer in tough environments, such as agriculture, mining, or food processing. Better materials lead to stronger, safer, and more efficient transmission systems.

Case 3

Surface Treatment Technology Innovation

We’ve developed several advanced surface treatments, including black oxidation, zinc plating, and nickel coating. These treatments improve resistance to rust, wear, and chemical corrosion. For example, in humid or outdoor environments, black oxide-treated sprockets show better performance and longer service life. We also offer specialized coatings for food-grade applications that meet safety standards. With these innovations, our products last longer and require less maintenance. Better surface protection means more value for our customers and better performance in demanding industries.