Sprocket

- DIN Metric Standards SprocketsNov 18,2025Learn everything about DIN metric sprockets, including DIN 8187, DIN 8188, and ISO standards. This guide explains dimensions, materials, heat treatment, applications, and how to choose the right metric sprocket for your machinery.

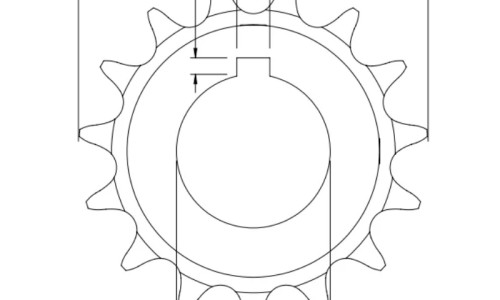

- Sprocket Size Chart:Complete ANSI &Metric Sprocket Dimensions GuideOct 10,2025Chain sprocket size chart covering ANSI and ISO standards. Learn how to choose the right sprocket size, understand key dimensions, and discover custom sprocket solutions from CTS China.

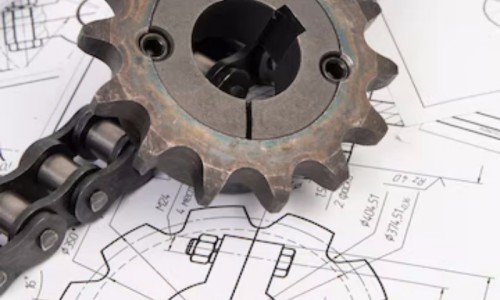

- ANSI Roller Chain SprocketSep 16,2025ANSI roller chain sprocket: types, materials, standards, and applications. Learn how to choose the right sprocket for your equipment with CTS.

- Industrial Sprockets: Complete Selection GuideMay 13,2025Industrial sprockets ensure efficient power transmission; choosing the right one boosts performance and equipment longevity.

- What Is Idler Sprockets?Jan 20,2025This guide will show you what is idler sprockets and the types of idler sprockets.

- 5 Signs of a High-Quality Industrial Sprocket ManufacturerNov 21,2024This guide will show you 5signs of a high-quality industrial sprocket manufacturer, helping you find a reliable industrial sprocket manufacturer.

- Custom Or Standard Industrial SprocketsNov 20,2024This guide will tell you which type of industrial sprocket to choose, standard or custom industrial sprockets.

- Top 5 Factors to Consider When Choosing an Industrial Sprocket ManufacturerNov 19,2024This guide will show you the top 5 factors to consider when choosing an industrial sprockets manufacturer.

- Maintenance Tips to Extend the Life of Your Industrial SprocketsNov 14,2024This guide will show you the essential maintenance tips to extend the life of your industrial sprockets.

- Industrial Sprocket Types and Their ApplicationsNov 6,2024This guide will show you the industrial chain sprocket types and their application in different industries.

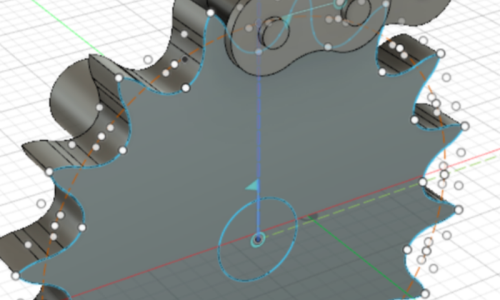

- The Custom Process for Industrial SprocketsOct 17,2024This guide will tell you the the custom process for industrial sprockets.

- How To Choose The Right Industrial Chain Sprocket for Your EnvironmentSep 30,2024This guide will help you choose the right chain sprockets for your environment.

Ask CTS?

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.

- China's professional power transmission manufacturer

- We offer customized product services and free samples to meet our customers' needs.

- Some of our products are mass-produced and kept in stock, ready for immediate shipment.

- Contact CTS

- Name