Home / All

News

- What is the industry sprocket used for ?Industry sprockets are widely used in various industrial applications for power transmission and motion control. They are essential components in machinery, equipment, vehicles, and conveyor systems. Sprockets engage with chains or belts to transmit rotary motion and power between rotating shafts. They are commonly found in industries such as manufacturing, automotive, transportation, agriculture, and logistics.Sep 12,2023

- What is the difference between roller chain and engineering chain?Roller chains are made up of cylindrical rollers connected by links and are commonly used in power transmission systems. Engineering chains, on the other hand, consist of interconnected, flat and elongated plates or links, and are often used in conveyor systems for material handling. The two types of chains have different designs, construction, applications, and load capacities.Sep 12,2023

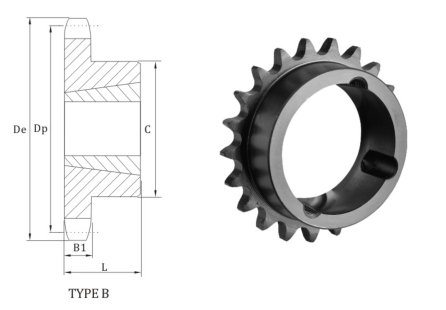

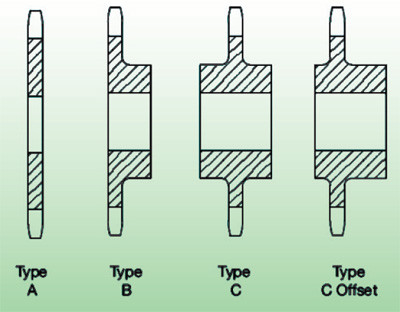

- what are taper bore sprockets and its advantageTaper bore sprockets are a type of sprocket used in various mechanical systems, especially in power transmission applications like conveyor systems, industrial machinery, and roller chains. These sprockets are designed with a tapered bore, which means the central hole (bore) through which they are mounted onto a shaft is tapered or conical in shape.Sep 11,2023

- what are taper bore sprockets and its advantageTaper bore sprockets are a type of sprocket used in various mechanical systems, especially in power transmission applications like conveyor systems, industrial machinery, and roller chains. These sprockets are designed with a tapered bore, which means the central hole (bore) through which they are mounted onto a shaft is tapered or conical in shape.Sep 11,2023

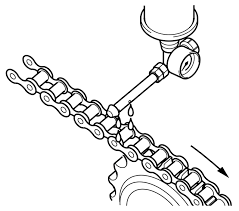

- Roller Chain Care and MaintenanceDirt and contaminants can cause premature wear and affect the performance of the roller chain. Regularly remove any accumulated dirt or debris from the roller chain using a brush or compressed air.Sep 11,2023

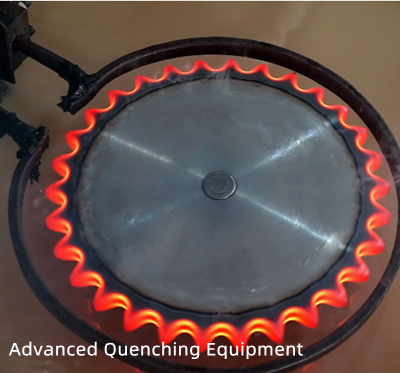

- What is Tooth Harding"Tooth harding" is a heat treatment process commonly used to enhance the hardness and wear resistance of gears and toothed components. In this process, gears or toothed components are first heated to a specific temperature, typically above the critical point, to alter their crystalline structure. Subsequently, rapid cooling, often using oil, water, or gas, is employed to cool the heat-treated region, thereby harding it.Sep 11,2023

- What are 3 types of sprocket?Sprockets are available with 1, 2 or 3 rows of teeth to suit the chain they are working with - simplex, duplex or triplex sprockets.Sep 8,2023

- How To Hobbing Inner Gear?Hobbing the inner gear is a common gear manufacturing process. The general steps for hobbing the inner gear include machine setup, workpiece preparation, hobbing cutter selection, tool setup, determination of cutting parameters, cutting operation, cooling and lubrication, quality control, and finishing steps. It requires specialized equipment and expertise, and the specific steps and techniques may vary depending on the machine and gear design requirements.Sep 5,2023

- How to Assemble large pitch chainPlease note that the process for assembling large pitch chains may vary based on the specific chain type and manufacturer's recommendations. Always refer to the product manual or manufacturer's instructions for the most accurate and detailed guidance.Sep 5,2023

- CNC Internal Gear MillingCNC internal gear milling is a machining process used to produce internal gears using a CNC (Computer Numerical Control) milling machine. It involves removing material from a workpiece to create the internal gear profile.Sep 5,2023

- How to use the sprockets?A roller chain sprocket is a type of sprocket that is specifically designed for use with a roller chain.Mar 31,2023

- Welcome To Visit Our Factory!Shengzhou Tomorrow Machinery started in 2011 and has a history of 12 years. Shengzhou Tomorrow Machinery can ensure every product produced meets strict quality standards. We are the professional sprockets manufacturer, all products are thoroughly inspected for accuracy throughout the manufacturing process.Dec 13,2022