DIN Metric Standards Sprockets

What are DIN Metric Sprockets?

DIN stands for Deutsches Institut für Normung, which is the German Institute for Standardization.DIN standards ensure that industrial components follow unified sizes, tolerances, and performance requirements.

A DIN metric sprocket is a sprocket designed to match metric roller chains, primarily defined by DIN 8187 and ISO 606. These sprockets are widely used in: Conveyor systems, Packaging machinery, Food processing equipment, Agricultural machinery, and General industrial machines.

Because DIN standards are globally recognized, DIN sprockets offer excellent interchangeability and reliability.

DIN Metric Sprocket Standards

DIN 8187

DIN 8187 is the most commonly used metric roller chain standard. It includes chain sizes such as:

| Sprocket Size | Pitch | Sprocket Size | Pitch | Sprocket Size | Pitch |

| 6 mm | 15.875 mm | 38.1 mm | |||

| 8 mm | 19.05 mm | 44.45 mm | |||

| 9.525 mm | 25.4 mm | 50.8 mm | |||

12.7 mm | 31.75 mm |

DIN 8187 Sprocket feature:

• Metric Pitch

• Standardized Hub Design

• Compatibility with ISO 606 Roller Chains

They are widely used in automation, conveyors, and various types of machinery.

DIN 8188

DIN 8188 is designed for heavy-duty operation. Compared to DIN 8187:

| Feature | DIN 8187 | DIN 8188 |

| Chain Plate | Standard | Thicker & Stronger |

| Roller Size | Normal | Larger |

| Application | General Machinery | Heavy Load & Shock Environment |

DIN 8188 sprockets are essentially reinforced versions of DIN 8187 sprockets.

ISO 606

ISO 606 is almost identical to DIN 8187. In most cases:

✔ DIN 8187 roller chains and ISO 606 roller chains are interchangeable

✔ Their chain sprockets also share the same dimensions

✔ The international compatibility is one reason why metric sprockets are widely used worldwide.

Understanding Metrc Sprocket Identification

To select or replace a DIN sprocket, you must understand the key parameters

Chain Pitch

Pitch is the distance between the centers of two roller pins

Number of Teeth

Sprocket teeth number affects speed ratio, torque transmisson, sprocket diameter

Bore Diameter

Standard sprocket bore include: plain bore, finished bore, taper bore

Keyway & Set Screws

Used to secure the sprocket to the shaft

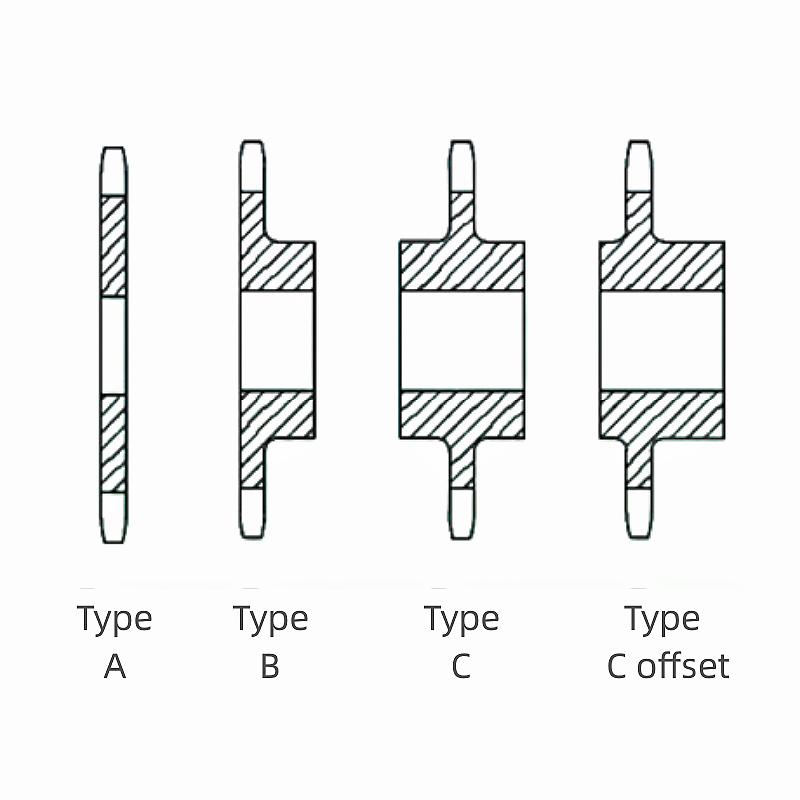

Hub Type

A type sprocket

Flet plate

B type sprocket

Single hub

C type sprocket

Double hub

DIN Sprockets VS ANSI Sprockets

| Feature | ||

| Measurement | Millimeters | #25-#240 |

| Pitch sizes | 04B-24B | American |

Interchangebility | ANSI and DIN sprockets cannot be interchanged due to pitch and profile differences. | |

Sprockets Heat Treatments

Heat treatment significantly improves sprocket lifespan.

Tooth Harending

Most DIN sprockets require induction hardening:

• Surface hardness: 40-50 HRC

• Depth: 0.2-2.0 mm

Carurizing

Used for high-load gears and sprockets

Surface Finishing

Coomon finishes: Black Oxide, Zinc-plating, Phosphate, Anti-rust Oil

These treatments enhance corrosion resistance and appearance.

As a professional industrial sprocket manufacturer, we have standard sprockets. And also can provide custom solutions to meet unique client needs.

If you have any needs, please contact us for help.

FAQs

Are DIN 8187 sprockets interchangeable with ANSI Sprockets?

No. They have different pitch systems and cannot be interchanged.

What is the difference between DIN 8187 and DIN 8188?

DIN 8187 is standard duty, while DIN 8188 is heavy-duty with thicker chain plates and larger chain rollers.