Split Sprockets: The Secret to Reducing Harvest Downtime from Hours to Minutes

The High Cost of the "Harvest Bottleneck"

When harvest begins, grain elevators and storage bins run 24/7. This is when your equipment is under the most stress. Dust, heat, and heavy loads put immense pressure on your conveyor chains and sprockets.

If a sprocket tooth wears down or breaks, the entire facility stops. In a traditional system, a "Solid" sprocket is keyed onto the head shaft. To replace it, maintenance teams must:

1) Disconnect the drive motor.

2) Remove the couplings.

3) Pull the bearings off the shaft.

4) Slide the old sprocket off and the new one on.

5) Reassemble and re-align everything.

This process can take 8 to 12 hours. In the middle of harvest, that is an eternity.

What Exactly is a Split Sprocket?

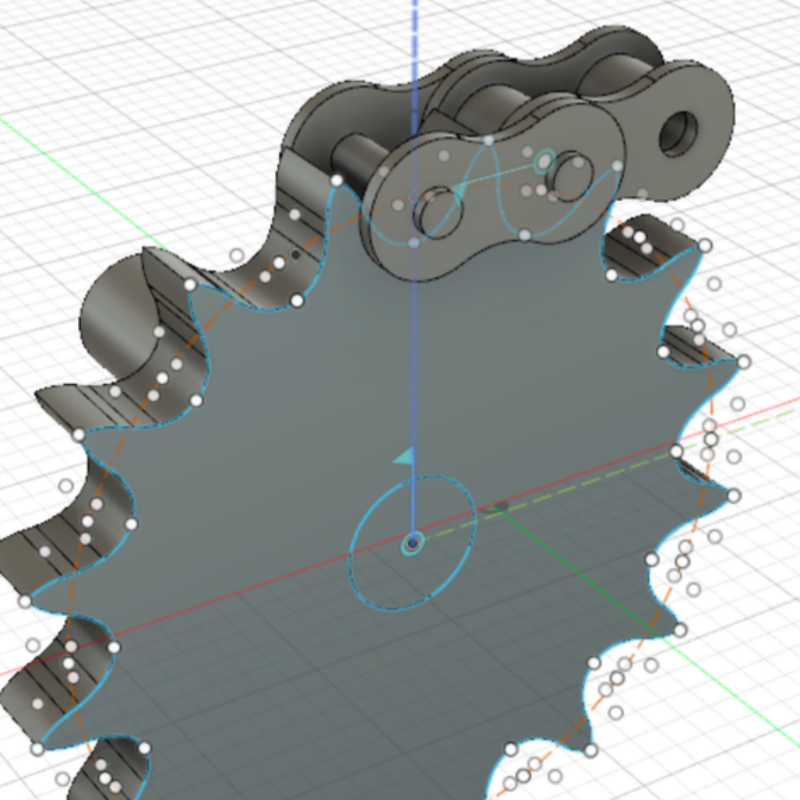

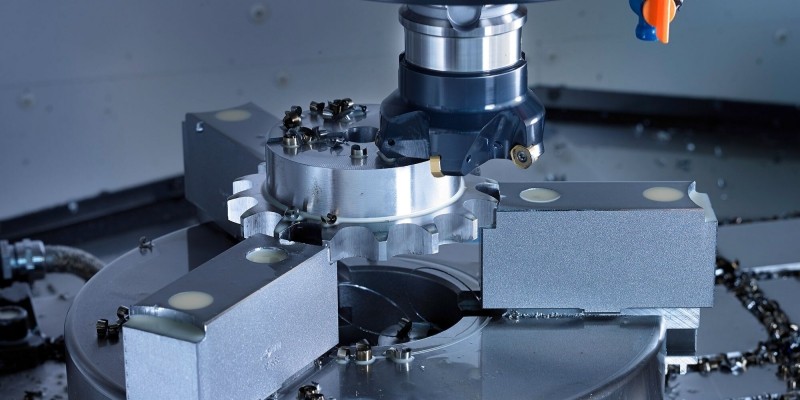

A split sprocket is a precision-engineered drive component manufactured in two or more segments. These segments are designed to bolt together securely around an existing shaft.

The Engineering Behind the Split

Unlike a solid sprocket that must be slid over the end of a shaft, a split sprocket "clamps" onto the shaft. High-strength bolts hold the halves together. When manufactured correctly, the "split line" (where the two halves meet) is so precise that the chain does not feel any gap.

Why Precision Machining Matters

For a split sprocket to work in a grain conveyor, it must be perfectly concentric. This means it must be a perfect circle once bolted together. If it is slightly "egg-shaped," it will cause the chain to vibrate. Our split sprockets are machined as a single unit, then split, and then match-marked to ensure a perfect fit every time.

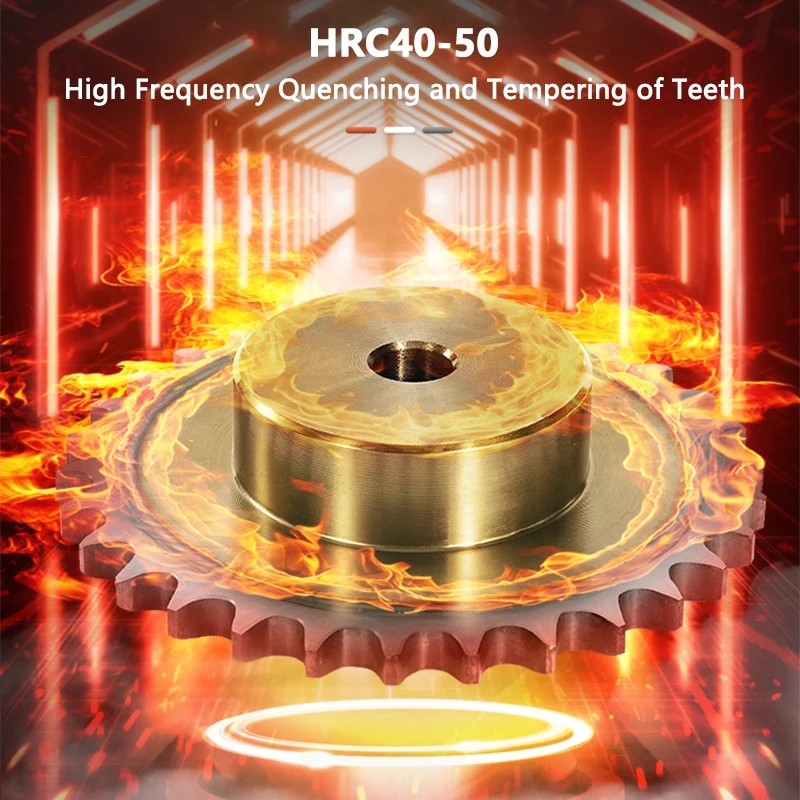

The Power of Induction Hardening (HRC 45-55)

Grain dust is the enemy of steel. Corn husks, dirt, and wheat chaff act as an abrasive "grinding paste." If you use a standard, soft steel sprocket, the dust will wear the teeth into a "hook" shape very quickly.

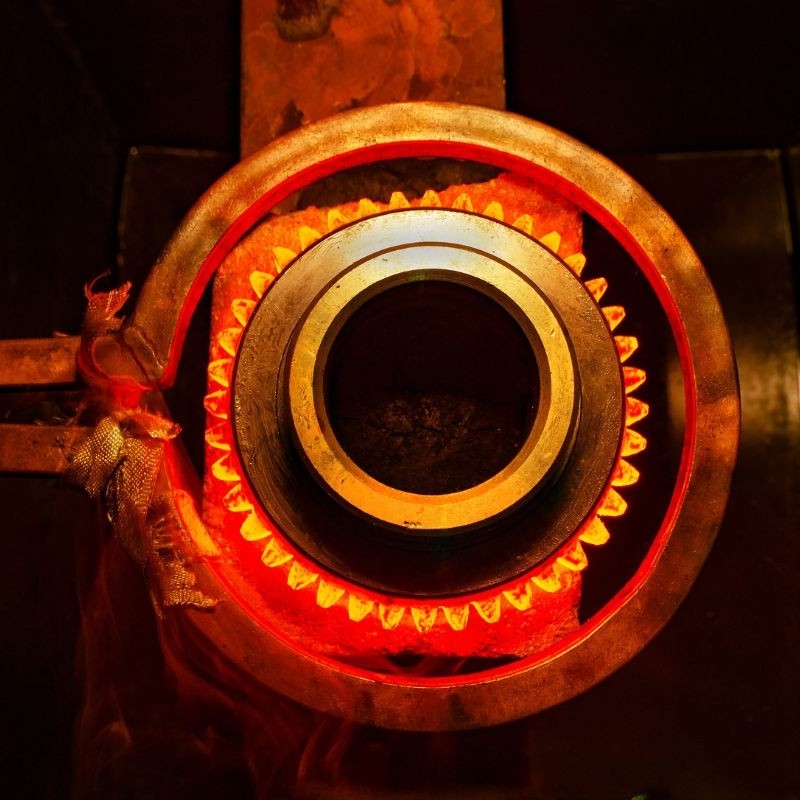

What is Induction Hardening?

We use high-frequency electricity to heat only the teeth of the sprocket to a very high temperature, followed by rapid cooling.

• The Result: The teeth become incredibly hard (Rockwell Hardness HRC 45-55), while the center of the sprocket remains "tough" and flexible.

• The Benefit: Hardened teeth can last 3 to 5 times longer in a dusty grain bin than non-hardened sprockets.

Depth of Hardness

It is not enough to just harden the surface. We ensure the "Case Depth" of the hardening is deep enough so that as the sprocket wears slightly over years of use, it remains hard and resistant to the abrasive grain.

Why Grain Storage Facilities are Switching to Split Sprocket

There are three main reasons why managers of large-scale silos and grain elevators are moving away from solid sprockets.

Key steps include:

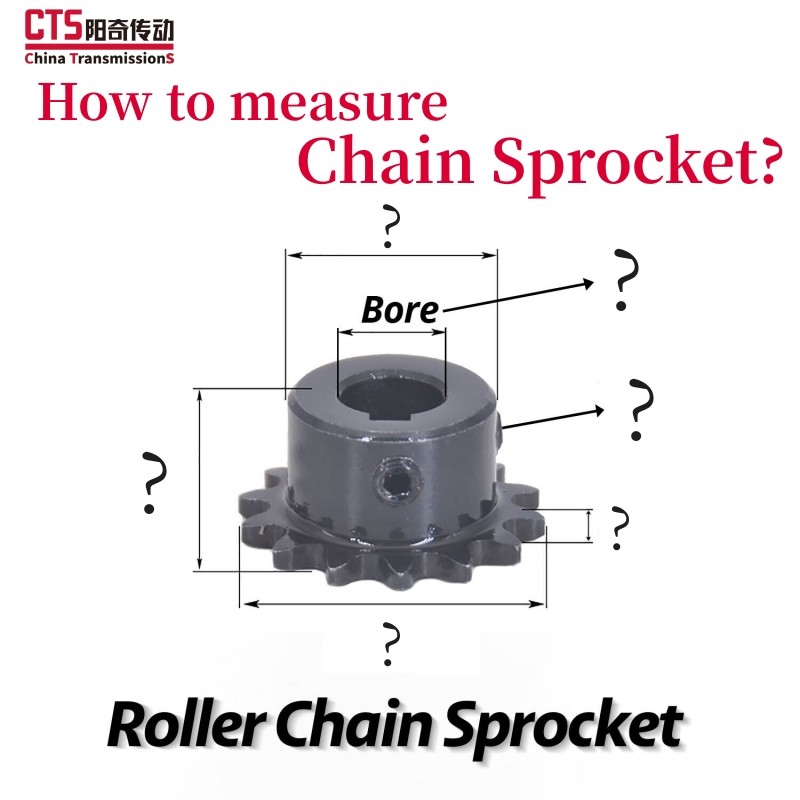

· CNC Machining: Ensures accurate pitch diameter and tooth geometry.

· Keyway Cutting &Bore Finishing: Guarantees proper shaft fit and alignment.

· Quality Control: Hardness testing, dimensional checks, fatigue testing.

Massive Labor Savings

As mentioned, replacing a solid sprocket requires a full team and an entire day.

With a Split Sprocket: You simply loosen the bolts, remove the old halves, and bolt the new halves onto the shaft.

Time Saved: You can complete a replacement in 30 to 60 minutes. You do not need to touch the bearings, the motor, or the couplings.

Safety First

Removing heavy head shafts (which can weigh hundreds of pounds) is dangerous. It involves heavy lifting, cranes, and many moving parts. Because split sprockets are installed while the shaft is still in place, the risk of workplace injury is significantly lower.

Reduced Maintenance Costs

You no longer need to hire a large outside contractor crew for a simple sprocket change. Your on-site maintenance person can handle the swap during a short lunch break or a scheduled shift change.

Technical Comparison: Solid vs. Split Sprockets

| Feature | Solid(Standard) Sprocket | Precision Split Sprocket |

| Installation Time | 8-12 Hours | 30-60 Minutes |

| Shaft Removal? | Yes (Complete teardown) | No (Shaft stays in place) |

| Replacement Labor | Require 3-4 workers | Require 1-2 workers |

Material | Standard Carbon Steel | 1045 Carbon Steel (Hardened) |

Total ROI | High maintenance cost | High initial, low long-term cost |

Split Sprocket Used in the Grain Handling

Where should you use split sprockets? Not every shaft needs one, but there are critical "high-pain" areas where they are essential.

Bucket Elevator Head Shafts

This is the most critical application. The head shaft is usually 30+ meters in the air. Carrying tools and heavy shafts up there is a nightmare. A split sprocket at the top of an elevator is the best investment a facility can make.

En-Masse Conveyors (Silo Distribution)

Conveyors that run across the top of multiple bins are often in cramped, dusty spaces. There isn't enough room to slide a solid sprocket off a long shaft. Split sprockets solve the "space constraint" problem.

Receiving Drag Conveyors

Because receiving pits are at ground level, they get the most dirt and rocks. This causes the highest wear. Using a split sprocket here allows for quick swaps during the peak of truck unloading.

The ROI Calculation: Does it make financial sense?

Let's look at a real-world scenario.

Scenario: A 10,000 bushel-per-hour grain elevator during harvest.

Cost of Downtime: $2,000 per hour (Labor, idle trucks, lost throughput).

Solid Sprocket Replacement: 10 hours downtime = $20,000 loss.

Split Sprocket Replacement: 1 hour downtime = $2,000 loss.

Even if a Split Sprocket costs $500 more than a solid one, you have saved $17,500 in a single afternoon. Over the 10-year life of a facility, the savings reach hundreds of thousands of dollars.

Maintenance Tips for Split Sprockets

To ensure your split sprockets last for many seasons, follow these three simple rules:

✔ Check Bolt Torque: After the first 24 hours of operation, check the bolts that hold the split halves together. Vibration can sometimes loosen them initially.

✔ Monitor the "Split Line": Look for any signs of the chain "clicking" as it passes over the join. This is a sign that the halves are not aligned.

✔ Inspect Tooth Profile: Once the teeth start to look like "shark fins" (hooked), it is time to order your replacement. Don't wait for the sprocket to fail.

CTS® | Professional Sprockets Factory

A split sprocket is more than just a piece of metal; it is a strategy for efficiency. By choosing induction-hardened split sprockets, grain facility managers protect their equipment from abrasion while protecting their schedule from unexpected breakdowns.

In the modern grain storage solution, the goal is "continuous flow." Nothing ensures continuous flow better than a drive system that can be repaired in minutes rather than days.

Ready to Upgrade Your Drive System?

Don't let a $500 part cause a $20,000 breakdown. Our team specializes in custom-machined split sprockets for every type of grain conveyor.

If you have any questions, please feel free to contact us.

CTS® professional technicians will be happy to help you!