Roller Chain Size Chart to Identify and Replace Chain?

Why Roller Chain Sizing Matters

Over time, roller chains wear out and need to be replaced. Choosing the wrong size chain can lead to serious problems such as machine downtime, damage, or even safety risks.

By learning to read the roller chain size chart, you can find the right chain size. You can also check for chain wear and replace it with the correct chain size.

What is a Roller Chain Size Chart?

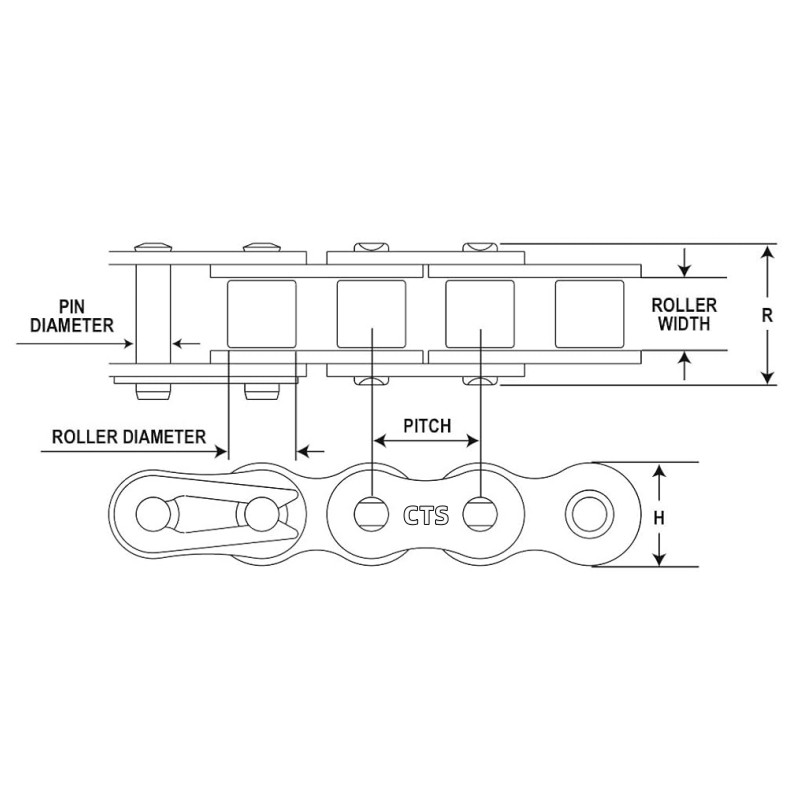

The roller chain size chart (or roller chain sizing chart) is a reference guide that shows the dimensions of different chain numbers. The chain dimension chart includes information such as:

· Pitch (center-to-center distance between pins)

· Roller diameter

· Inner width

· Pin diameter

· Standard reference (ANSI/ISO/DIN)

These chain sizing charts follow international standards. Therefore, you can easily compare and match chains, regardless of the machine's country of origin.

Key Dimension in Roller Chain Sizing Chart

To use a roller chain size chart correctly, you need to understand the main dimensions:

1.Pitch(P)

Pitch is the distance between the centers of two consecutive pins in the chain. The most important measurement when identifying a roller chain.

2.Roller Diameter(d1)

This is the outer diameter of the roller. It helps the chain roll smoothly on the sprocket teeth.

3. Inner Width (b1)

This is the distance between the two inner plates of the roller chain. It determines the width of the sprocket teeth that the chain will fit.

4. Overall Length and Number of Links

For roller chain replacement, you may also need to count the total number of chain links.

How to Identify Your Roller Chain

If you already have roller chains, but don't know their size, follow these steps to identify them:

Step 1: Measure the Chain Pitch

Use a caliper or ruler to measure the distance between the centers of two pins.

Step 2: Measure the Roller Diameter

Measure the outer diameter of one of the rollers.

Step 3: Measure the Inner Width

Measure the inside distance between the two inner plates.

Step 4: Compare with the Roller Chain Size Chart

Now, take these measurements and compare them with the values in a roller chain sizing chart. This will let you know the exact chain number (such as #40, #50, 08B, etc.)

When Should You Replace Roller Chain

Even the best roller chains wear out over time. Here are some common signs that it's time to replace your chain:

· The chain has stretched and no longer fits the sprocket correctly.

· Visible wear on the rollers or plates.

· Unusual noise or vibration during operation.

· Frequent jumping or slipping off the sprocket.

The roller chain size chart helps you identify the correct replacement size quickly, saving time and reducing downtime.

How to Replace Roller Chains Correctly

Step 1: Select the Correct Chain

Use the roller chain size chart to find the correct size that matches your machine.

Step 2: Remove the Old Roller Chain

Use a roller chain breaker tool to safely remove the old chain.

Step 3: Install the New Chain

Place the new chain onto the sprockets and connect it with a master link.

Step 4: Lubrication and Maintenance

Apply proper lubrication to extend the life of the new chain.

Downloadable Roller Chain Size Chart

Here is a quick reference table of common ANSI roller chain sizes:

Click to see more roller chain sizes, like multi-strand roller chains, which provide higher tensile strength and load capacity, suitable for heavy-duty machinery.

CTS — Your Trusted Roller Chain Manufacturer

We are a professional roller chain manufacturer with years of experience in producing standard and custom roller chains.

✔ Custom chain solutions for special machinery

✔ Strict quality testing to ensure durability

If you are not sure which roller chain size to choose, send us your measurements. We will help you find the right chain using our size chart.

Contact us for more roller chain details.

Using a roller chain size chart is the fastest and most reliable way to identify your existing roller chain and replace it with the correct one. By measuring pitch, roller diameter, and inner width, you can quickly find the right size from the chart.

At CTS, we provide not only standard chains but also custom solutions to meet your specific requirements. With our expertise, you can be confident in choosing the right roller chain every time.

Durable Roller Chain Selection

ANSI Roller Chain

Metric Roller Chain

Heavy-duty Roller Chain

Stainless Steel Roller Chain

FAQs

How Do I Measure A Roller Chain If It′S Already Worn?

Even if the chain wears, measure the pitch and roller diameter as accurately as possible. Then compare it with a roller chain sizing chart to find the closest match.

How often should roller chains be replaced?

It depends on usage and environment, but you need to inspect roller chains regularly. Replace them when they show signs of wear, stretch, or noise.

What′s the difference between ANSI and ISO size charts?

ANSI roller chain charts are based on American standards, while ISO/DIN roller chain charts follow international standards. Some dimensions are slightly different, so always check your equipment requirements.