Innovation Design and Manufacturing Solution For Conveyor Chain Sprockets

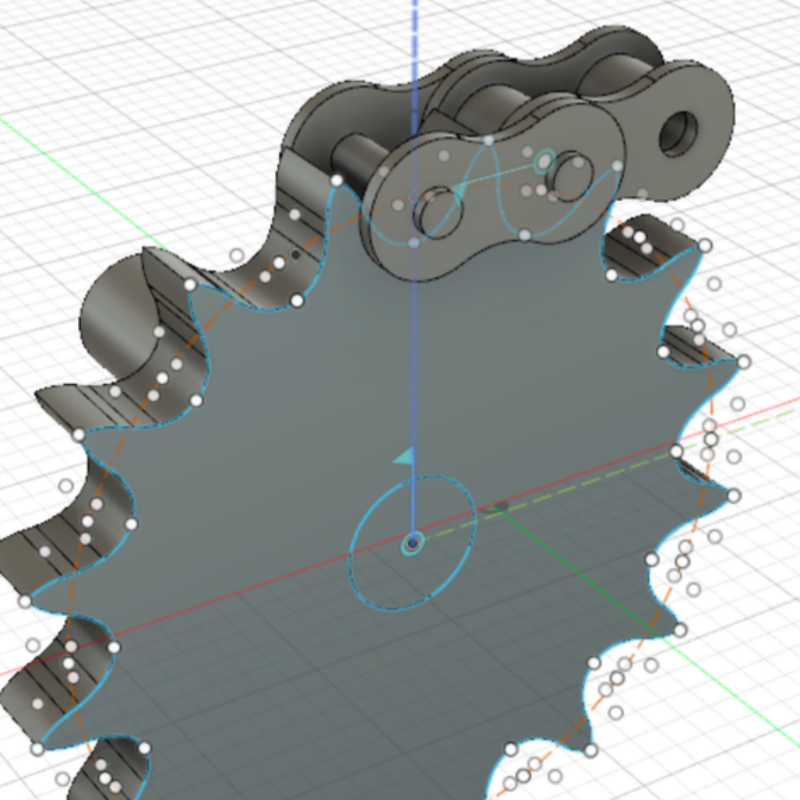

Odd VS. Even Sprocket Tooth Configurations

Tooth configuration is a critical factor in sprocket performance. Designers often choose between odd-numbered teeth and even-numbered teeth, depending on application needs.

Odd Number Teeth (e.g.,13,17,19):

✔ Advantage: Reduces repetitive wear on the same chain link, distributing load evenly.

✔ Advantage: Extends chain life by alternating the engaging links.

✘ Limitation: May cause slight vibration in some systems.

Even Number Teeth(e.g.,12,16,20):

✔ Advantage: Provides smoother rotation in high-speed applications.

✔ Advantage: Easier to manufacture in standardized sizes.

✘ Limitation: Increases repetitive stress on certain chain links.

Application Tip:

Use odd-number sprockets for heavy-duty, low-speed conveyors to maximize chain life.

Use even-number sprockets for high-speed conveyors where vibration control is critical.

Material Selection for Conveyor Chain Sprocket

The material used directly impacts sprockets' durability and performance. Different industries require different solutions:

| Material | Advantages | Applications |

| Carbon Steel | Strong, suitable for most conveyors | General industry |

| Cast Iron | High wear-resistance, good damping properties | Heavy-duty conveyors |

| Stainless Steel | Corrosion-resistant, hygienic | Food & beverage, pharma |

Alloy Steel | Superior strength, suitable for heat treatment | Mining, cement, heavy loads |

Choosing the right material helps balance cost, performance, and lifespan. For example, food-grade conveyors almost always require stainless steel sprockets.

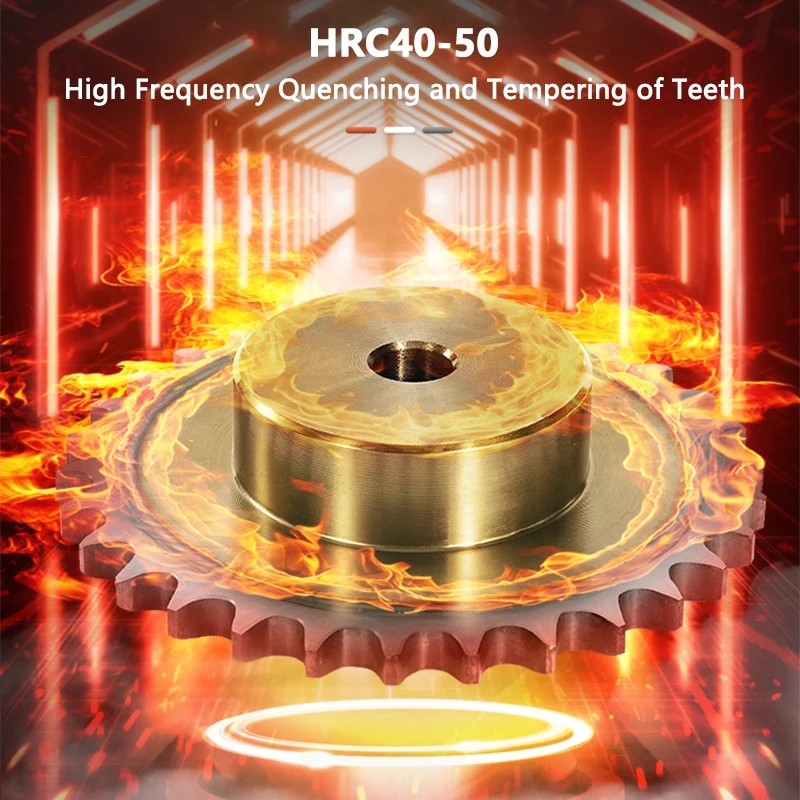

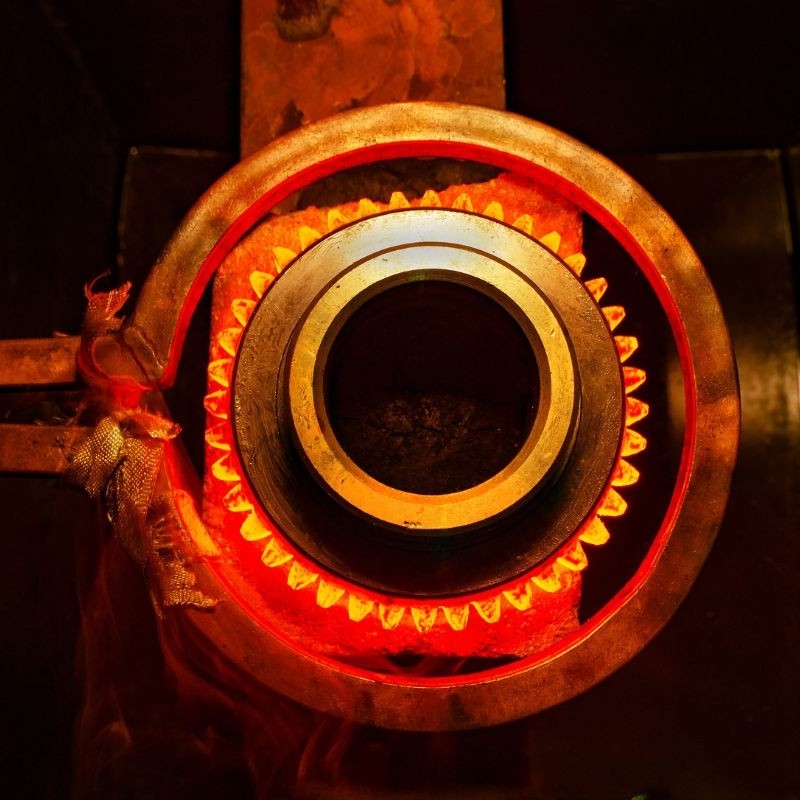

Heat Treatment and Surface Hardening Techniques

Conveyor chain sprockets endure constant contact and load from chains, so heat treatment is essential.

Common sprocket heat-treatment techniques

Case Hardening

Hardens the tooth surface while maintaining a tough core

Through Hardening

Ensures consistent hardness throughout the sprocket

Induction Hardening

Targets only the tooth area for improved wear resistance

Sprocket surface treatments

Black Oxide

Adds corrosion resistance, reduces glare

Zinc Plating

Protects against rust in moderate environments

Nitriding

Creates a hard,wear-resistant outer layer

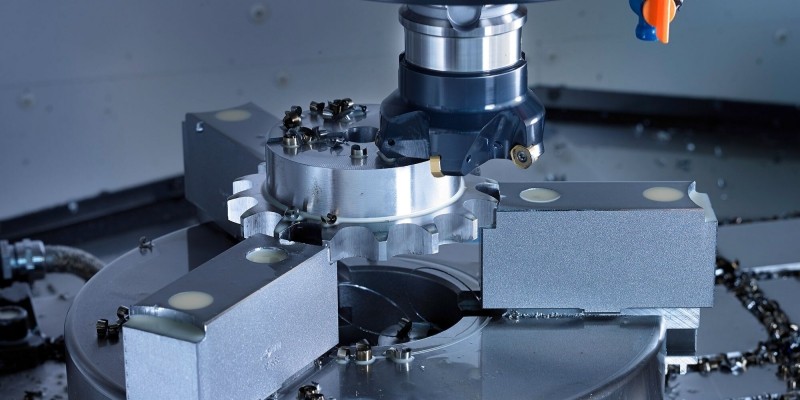

Precision Manufacturing Processes

Modern sprocket manufacturing combines traditional methods with CNC precision.

Key steps include:

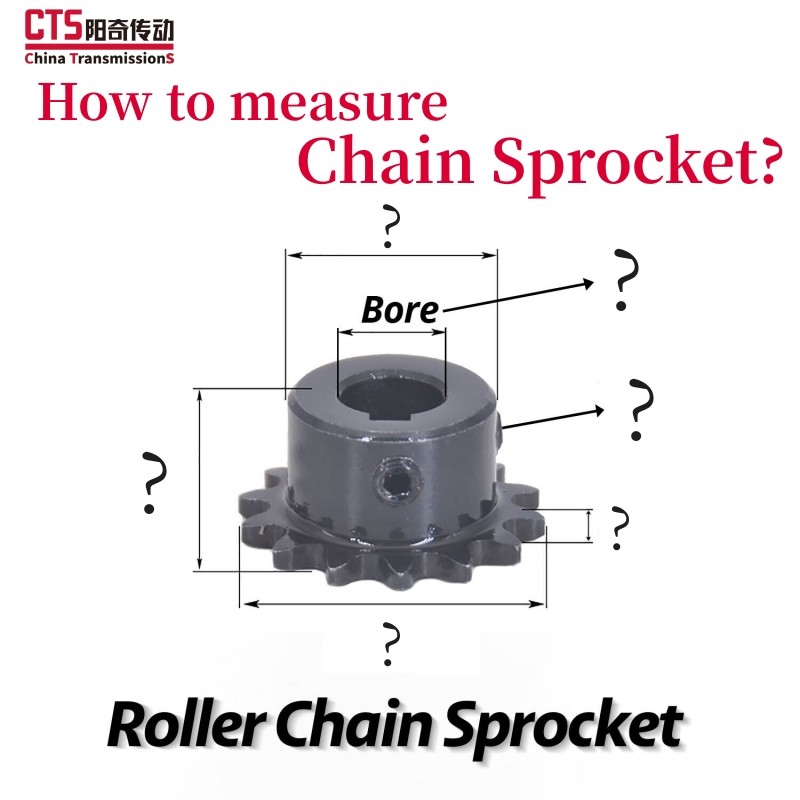

· CNC Machining: Ensures accurate pitch diameter and tooth geometry.

· Keyway Cutting &Bore Finishing: Guarantees proper shaft fit and alignment.

· Quality Control: Hardness testing, dimensional checks, fatigue testing.

Choosing the Right Conveyor Chain Sprockets

Selecting the correct sprocket requires consideration of:

1. Chain Compatibility-Match sprocket pitch and tooth count with chain specifications.

2. Operating Environment-Corrosive,high-temperature, or hygienic environments demand specific materials and coatings.

3. Maintenance Requirements-Choose designs that allow easy replacement or reduced lubrication needs.

CTS® | Professional Sprockets Factory

As a professional industrial sprocket manufacturer, CTS-ChinaTransmissionS offers a comprehensive range of high-quality sprockets.

If you have any questions, please feel free to contact us.

CTS® professional technicians will be happy to help you!

FAQs

What makes conveyor chain sprockets different from roller chain sprockets?

Conveyor sprockets are typically larger, designed for heavier loads, and customized for slow-moving conveyor applications, while roller chain sprockets are used in high-speed power transmission.

How does heat treatment improve Conveyor Chain sprocket life?

Heat treatment hardens the tooth surface, making it more resistant to wear while maintaining core toughness to handle heavy loads.