ANSI Roller Chain Size Chart | Dimension Guide

Roller chains are essential components in many machines. Since different equipment has different requirements for chain strength and size, choosing the right specification is especially important.

The ANSI Roller Chain Size Chart provides a standard guide to help users quickly select the correct chain for reliable performance.

What Is ANSI Roller Chain

ANSI stands for the American National Standards Institute. The roller chain standard created by ANSI (ANSI B29.1) is widely used in North America and around the world.

ANSI roller chains are known for:

✔ Standardized sizes and specifications, making them interchangeable.

✔ Common use in industrial drives, agricultural machinery, and conveyor systems.

Compared to ISO or BS standards, ANSI chains are the most common type used in the North American market.

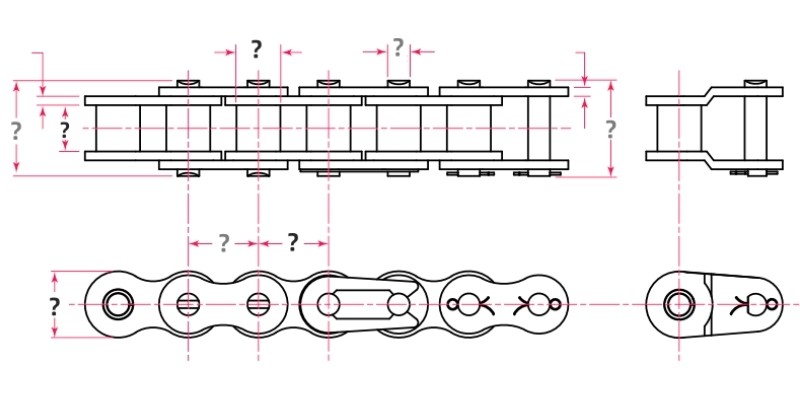

Key Components of Roller Chain

Before looking at the size chart, it's helpful to understand a few key terms:

Chain Pitch: The distance between the centers of two adjacent pins. This is the main measurement for identifying a chain's size.

Roller Diameter: The diameter of the roller. This affects how smoothly the chain engages with the sprocket.

Inner Width: The distance between the inner link plates. It determines the chain's fit with the sprocket teeth.

Pin Diameter: The diameter of the pin. A larger diameter generally means higher strength.

Plate Height & Thickness: The dimensions of the side plates. These relate to the chain's overall strength and durability.

Ultimate Tensile Strength: The maximum pulling force a chain can handle before breaking.

Weight per Meter: The weight for one meter of chain, useful for calculating the total weight.

ANSI Roller Chain Size Chart

How To Choose ANSI Roller Chain Size

Selecting the correct roller chain size involves considering several key factors:

Chain Load and Strength

Light-duty machinery: Often uses #40 and #50 roller chains

Medium-duty machinery: Commonly used series #60 and #80 roller chains

Heavy-duty machinery: Typically requires #100 roller chains and above.

Operating Speed

For high-speed applications, choose roller chains with a smaller roller diameter and lower friction.

Working Environment

For wet or corrosive environments, stainless steel roller chains are recommended.

For high-wear conditions, consider roller chains with nickel plating or hardened surfaces.

ANSI Roller Chain Size and Application

ANSI 40 Roller Chain: Light-duty machinery, food processing equipment.

ANSI 80 Roller Chain: Commonly used in conveyor lines and agricultural machinery.

ANSI 160 Roller Chain: Primarily for heavy-duty engineering equipment and mining machinery.

Standardized roller chain sizing allows users to find the right model more efficiently.

ANSI Roller Chain VS. Metric Roller Chain

| Standard | ANSI B29.1 | ISO 606/DIN8187 or 8188 |

Measurement Unit | Inch | Millimeter |

Chain Pitch | 1/4", 3/8", 1/2", 5/8", etc. | 6mm, 8mm, 10mm, 12.7mm. etc. |

Common Chain Size | #25, #35, #40, #50, #60, #80, etc. | 06B, 08B, 10B, 12B, 16B,etc. |

Application Regions | North America, Japan, parts of Asia | Europe, parts of Asia |

You may come across two commonly used sizes: #40 roller chain and 08B roller chain; they have the same pitch — 1/2 inch (12.7 mm).

Even if the chain pitch seems close, other dimensions—like roller width, plate height, and pin diameter—can vary enough to:

Causes improper sprocket engagement, increases wear and vibration, and leads to premature failure, so they are interchangeable.

CTS — Roller Chain Manufacturer

The ANSI Roller Chain Size Chart is a vital tool for engineers and buyers. Its standardized parameters help users quickly select the correct chain, improving equipment reliability and efficiency.

As a professional chain manufacturer, CTS offers a full range of ANSI Roller Chains and can also provide custom solutions based on your specific needs.

If you need any help, please contact us.