Wholesale Supply

For You

150,000 Products

Complete variety

More than 14 Years

Trust and experience

ANSI, ISO

Satisfaction guaranteed

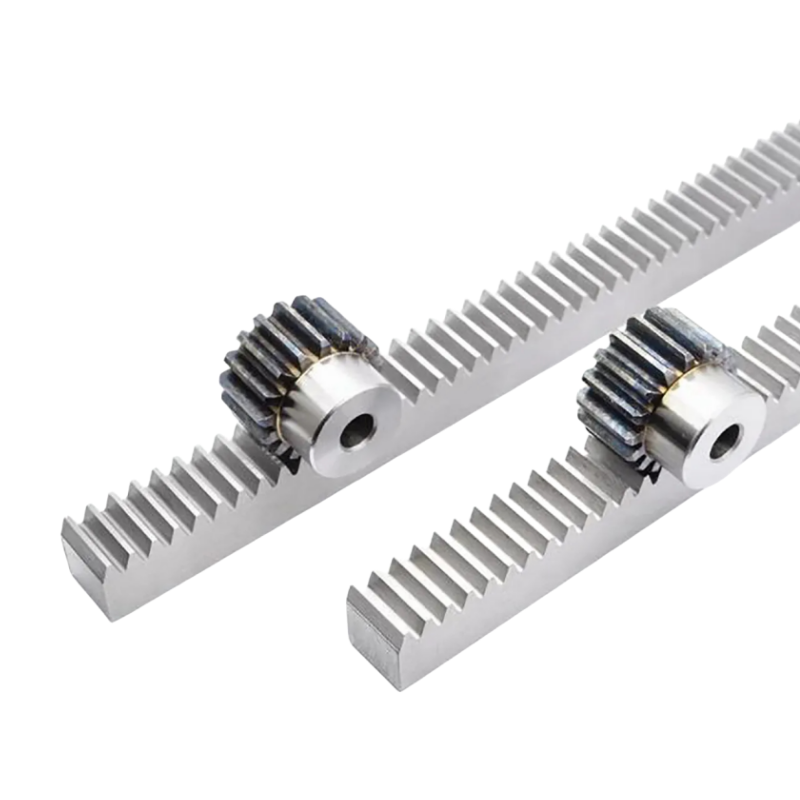

Imperial Spur Gears

Imperial Steel Spur Gear

Imperial Spur Gears are gears manufactured according to imperial diametral pitch(DP) standards rather than metric module systems. The DP value represents the number of teeth per inch of the gear's pitch diameter.

They are typically used in equipment imported from or designed for regions using the imperial system, ensuring compatibility and easy replacement.

Should you require technical assistance or guidance in selecting the optimal imperial spur gears for your specific application, please don't hesitate to reach out to us.

Main features:

· Straight teeth parallel to the shaft

· Consistent torque transmission with minimal noise

· Accurate tooth form for smooth operation

· Available in carbon steel, alloy steel, or stainless steel

Imperial Steel Spur Gear Type

Imperial Spur Gear Selection

High-quality imperial spur gears from CTS-ChinaTransmissionS — a trusted gear manufacturer offering durable, precisely machined DP gears from 4DP to 64 DP. Custom bore sizes, materials, and heat treatments available.

| Image | Imperial Spur Gears | Description | In stock | More |

|---|---|---|---|---|

| 6DP Imperial Steel Spur Gear | Imperial Spur Gear is a precision-engineered component for industrial machinery, ensuring reliable performance and operation. | In Stock | |

| 5DP Imperial Steel Spur Gear | Imperial Spur Gear is a precision-engineered component for industrial machinery, ensuring reliable performance and operation. | In Stock | |

| 4DP Imperial Steel Spur Gear | Imperial Spur Gear is a precision-engineered component for industrial machinery, ensuring reliable performance and operation. | In Stock | |

| 3DP Imperial Steel Spur Gear | Imperial Spur Gear is a precision-engineered component for industrial machinery, ensuring reliable performance and operation. | In Stock |

How to Select the Right Imperial Spur Gear

When choosing the right gear, consider:

DP (Diameteral Pitch): Must match the mating gear for proper meshing

Number of Teeth: Determines gear ratio and torque

Bore Size & Keyway: Ensure proper shaft fit

Material & Surface Finish: Choose based on load and environment

Heat Treatment: Required for high-speed or heavy-duty applications

If you're unsure, CTS technicians can help you select the proper gear dimensions and specifications.

Related Products

Why Choose CTS Spur Gear

• Precision Machining: Each spur gear is produced with CNC machining and gear hobbing to ensure perfect tooth geometry

• Heat Treatment Option: Full hardening, surface hardening, or carburizing improves wear resistance and load capacity

• Material Variety: Choose from carbon steel, alloy steel, stainless steel, or other specified materials

• Custom Bore & Keyway: Machined according to customer drawings or sample requirements

• Durability & Consistency: Manufactured for long service life and stable torque transmission

Ask CTS?

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.

- China's professional power transmission manufacturer

- We offer customized product services and free samples to meet our customers' needs.

- Some of our products are mass-produced and kept in stock, ready for immediate shipment.

- Contact CTS

- Name