Wholesale Supply

For You

150,000 Products

Complete variety

More than 14 Years

Trust and experience

ANSI, ISO

Satisfaction guaranteed

MH Couplings

- What

- Products Type

- Select Products

- Why CTS

MH Coupling

HRC Coupling Technical Data

Service Factor

Driven Machine | Driver Machine | |||

Operating type |

Examples

|

Electric Motor |

Engine type

|

|

|

4 or more Cyl.

|

3 or less Cyl.

|

|||

Slightly shock |

Centrifugal fan and pumps, agitator for light liquid, light generator, conveyor belt, brewing machinery.

|

1.0-1.2 |

1.5-1.7

|

2.0-2.2

|

Medium shock |

Crane hoists, wood machinery, textile machinery, paper mill machinery, machine tools, centrifugal pump for loaded liquid.

|

1.5-1.7 |

2.0-2.5

|

2.5-3.0

|

Heavy shock | Crusher, shakers, calender, reciprocating conveyor, welding set, heavy rolling mill, rubber machinery. | 2.0-2.2 | 2.5-3.5 | 3.0-4.0 |

HRC Coupling Selection

| Image | MH Couplings | Description | In stock | More |

|---|---|---|---|---|

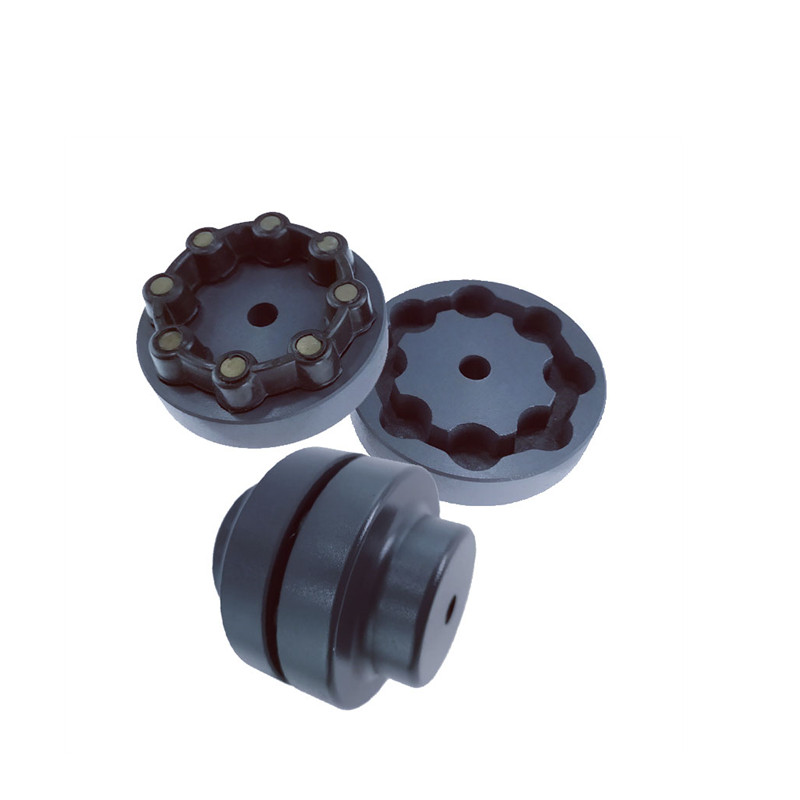

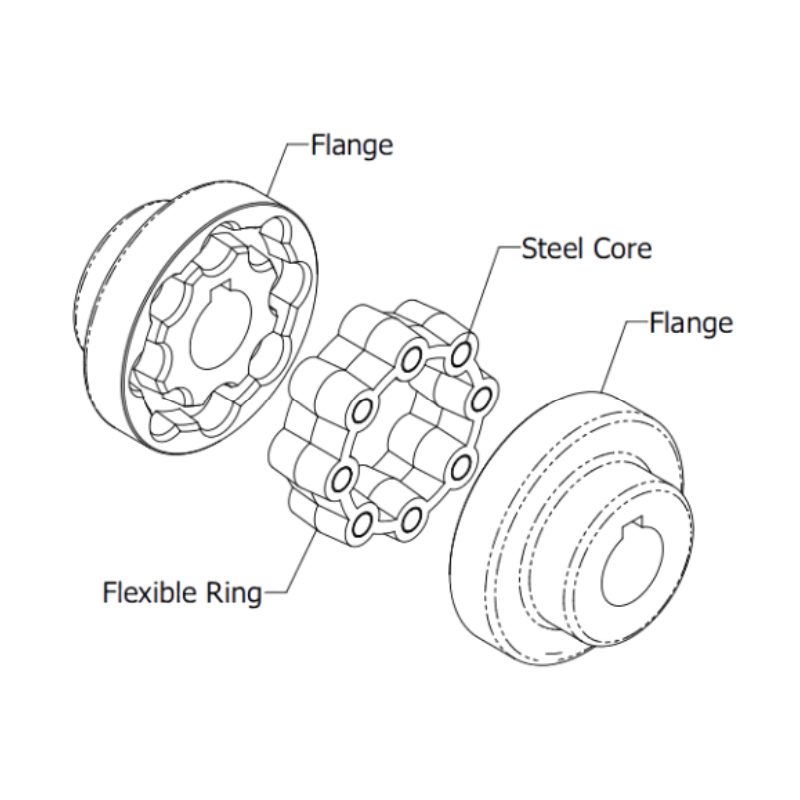

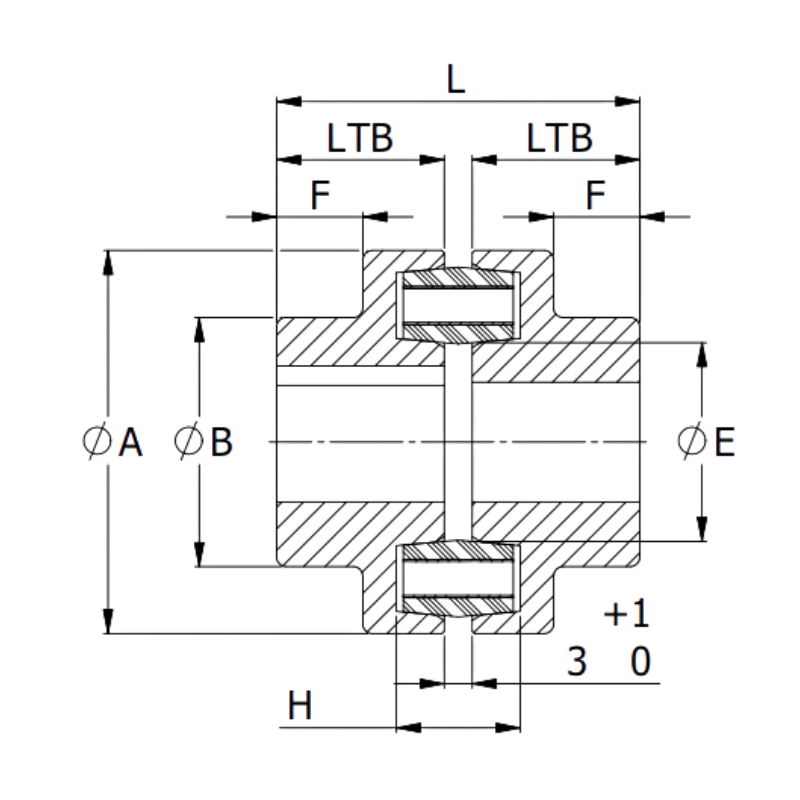

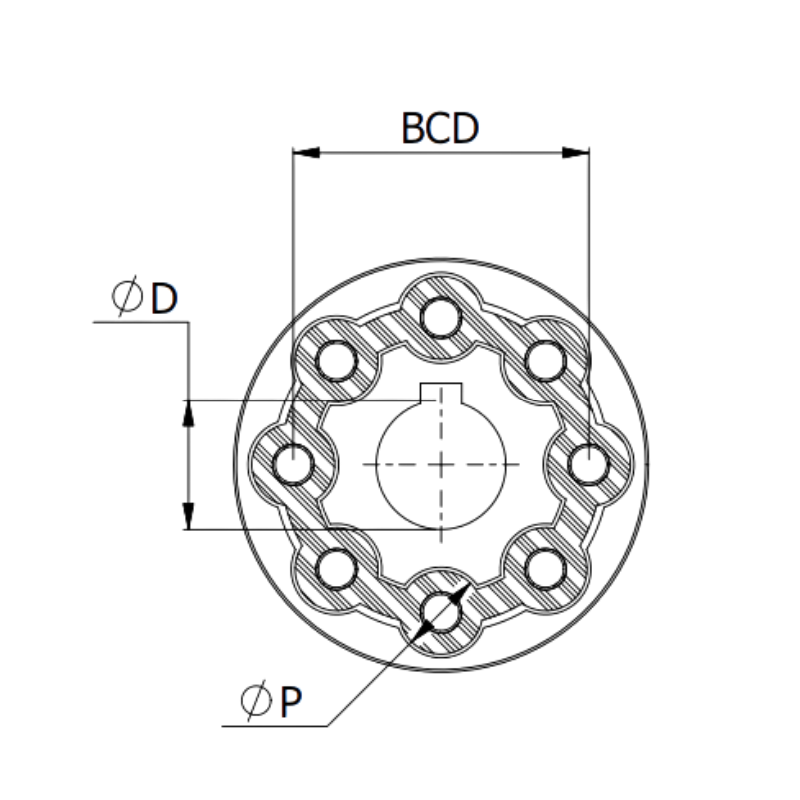

| MH 200 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock | |

| MH 175 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | Email/Call | |

| MH 145 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock | |

| MH 130 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock | |

| MH 115 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock | |

| MH 90 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock | |

| MH 80 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | Available Now | |

| MH 65 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock | |

| MH 55 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock | |

| MH 45 Coupling | MH couplings offer flexible rings with steel cores for compensating misalignment, and vibration absorption. | In Stock |

About CTS® MH Coupling

Professional MH Coupling Supplier

Your Trusted Partner in MH Coupling Manufacturing

CTS's Commitment

High-quality materials and manufacturing:

We prioritize quality and customer satisfaction as our differentiators.

Pursuit of perfection:

We strive to be the “best” in all our actions.

Customer-centric approach:

We value our customers’ needs and treat them as our roadmap.

Continuous Innovation:

Research and development are core values for our growth and success.

Global Vision:

Transmit Force, Dirve Future. We aspire to become a globally renowned company that drives a more sustainable future with high-quality industrial transmission products.

Ask CTS?

Having trouble finding the product you need? Send us an email with your question or message, and we'll quickly respond with tailored solutions. We're eager to hear from you! Expect top-notch precision, reliability, efficiency, and performance. Let's redefine excellence together.

- China's professional power transmission manufacturer

- We offer customized product services and free samples to meet our customers' needs.

- Some of our products are mass-produced and kept in stock, ready for immediate shipment.

- Contact CTS

- Name