What is Hobbing

Hobbing

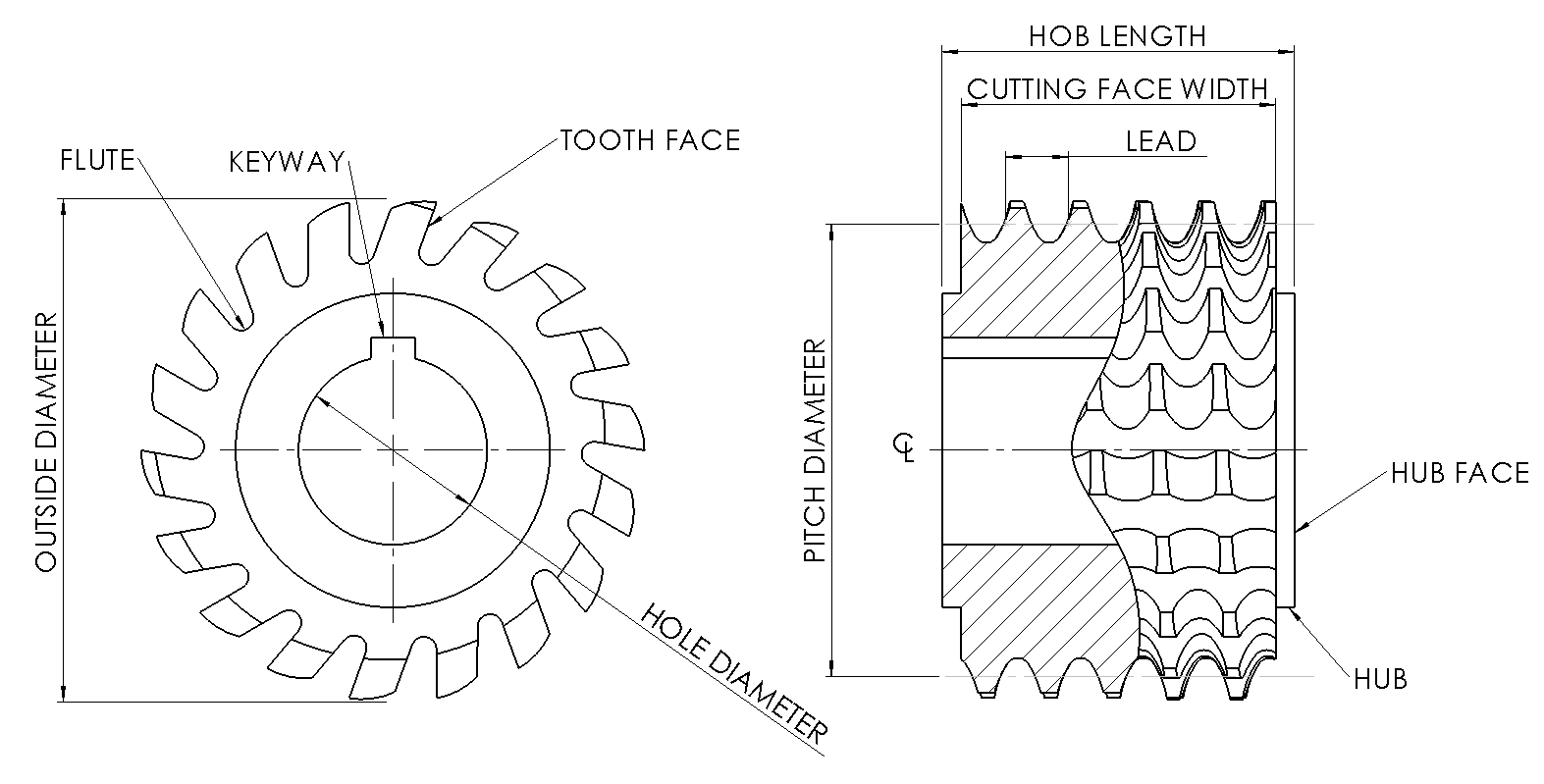

Hobbing is a machining process for gear cutting, cutting splines, and cutting sprockets on a hobbing machine, which is a special type of milling machine. The teeth or splines of the gear are progressively cut into the material (a flat, cylindrical piece of metal) by a series of cuts made by a cutting tool called a hob. Compared to other gear forming processes it is relatively inexpensive but still quite accurate, thus it is used for a broad range of parts and quantities.

It is the most widely used gear cutting process for creating spur and helical gears and more gears are cut by hobbing than any other process as it is relatively quick and inexpensive.

A type of skiving that is analogous to the hobbing of external gears can be applied to the cutting of internal gears, which are skived with a rotary cutter (rather than shaped or broached).

Process

Hobbing uses a hobbing machine with two skew spindles, one mounted with a blank workpiece and the other with the hob. The angle between the hob's spindle (axis) and the workpiece's spindle varies, depending on the type of product being produced.

For example, if a spur gear is being produced, then the hob is angled equal to the lead angle of the hob; if a helical gear is being produced then the angle must be increased by the same amount as the helix angle of the helical gear. The hobbing features for gears are straight, helical, straight bevel, face, crowned, worm, cylkro and chamfering. The two shafts are rotated at a proportional ratio, which determines the number of teeth on the blank; for example, for a single-threaded hob if the gear ratio is 40:1 the hob rotates 40 times to each turn of the blank, which produces 40 teeth in the blank. If the hob has multiple threads the speed ratio must be multiplied by the number of threads on the hob.

The hob is then fed up into the workpiece until the correct tooth depth is obtained. Finally the hob is fed through the workpiece parallel to the blank's axis of rotation.

Often, during mass production multiple blanks are stacked using a suitable fixture, then cut in one operation.

For very large gears the blank can be gashed to the rough shape first to make hobbing easier.

Equipment

Hobbing machines, also known as hobbers, are fully automated machines that come in many sizes, because they need to be able to produce anything from tiny instrument gears up to 10 ft (3.0 m) diameter marine gears. Each gear hobbing machine typically consists of a chuck and tailstock, to hold the workpiece or a spindle, a spindle on which the hob is mounted, and a drive motor.

For a tooth profile which is a theoretical involute, the fundamental rack is straight-sided, with sides inclined at the pressure angle of the tooth form, with flat top and bottom. The necessary addendum correction to allow the use of small-numbered pinions can either be obtained by suitable modification of this rack to a cycloidal form at the tips, or by hobbing at other than the theoretical pitch circle diameter. Since the gear ratio between hob and blank is fixed, the resulting gear will have the correct pitch on the pitch circle, but the tooth thickness will not be equal to the space width.

Hobbing machines are characterised by the largest module or pitch diameter it can generate. For example, a 10 in (250 mm) capacity machine can generate gears with a 10 in pitch diameter and usually a maximum of a 10 in face width. Most hobbing machines are vertical hobbers, which means the blank is mounted vertically. Horizontal hobbing machines are usually used for cutting longer workpieces; i.e. cutting splines on the end of a shaft.

Contact Us-Welcome To Send Us Inquiries!!!

Taylor Chan

Hangzhou YangQi Imp&Exp Co.,Ltd

杭州阳奇进出口有限公司

Room 1310,Taotiandi Buliding 2,Jianggan District,Hangzhou City ,Zhejiang

sales1@chinatransmissions.com

Mob/Whatsapp:+8618857038600

Wechat:lemonchen77

www.chinatransmissions.com