What Is Roller Chain Tensile Strength?

What Is Roller Chain Tensile Strength

Tensile Strength:

Maximum load (in kN or lbs) a chain withstands before fracture under quasi-static tension.

Distinction from Working Load:

Tensile strength = ultimate breaking point;

Working load requires a safety margin (typically 1/4 to 1/6 of the tensile strength).

Tensile strength serves as a critical safety threshold and foundational design parameter for preventing failures, ensuring that roller chains perform reliably under load.

slow Down

Key Factors Affecting Tensile Strength

Material & Manufacturing

Steel Grade:

High-carbon steel (e.g., SAE 4340) > Alloy steel > Mild steel; stainless steel (corrosion-resistant but lower strength).

Heat Treatment:

Carburizing/quenching pins & bushings enhances wear resistance and tensile strength.

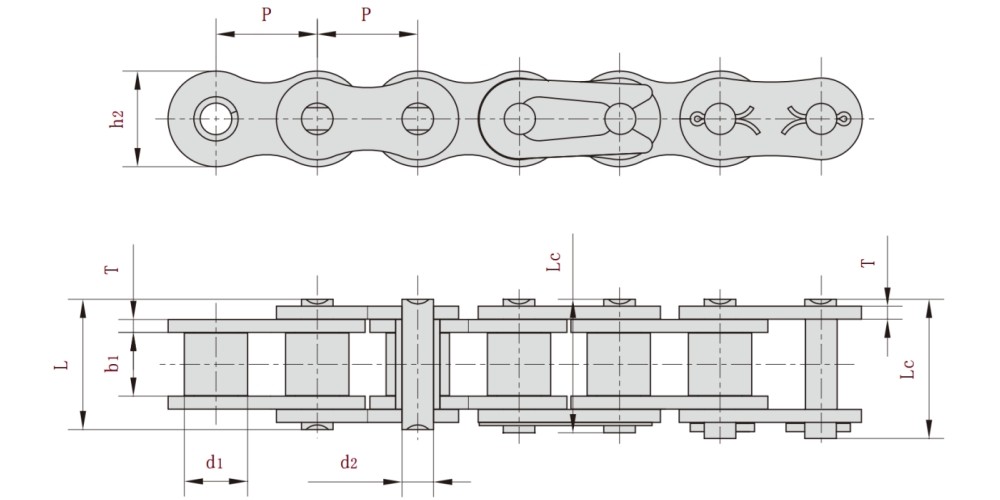

Structural Design

Chain Pitch Size:

Larger pitch = higher load capacity (e.g., #80 > #40) but reduced smoothness.

Multi-Strand Configurations:

Duplex roller chain (2x strength), Triplex roller chain (3x strength) VS. single-strand roller chains.

Link Plate Geometry:

"Figure-8" plates optimize stress distribution, minimizing localized fractures.

Quality Control

Dimensional Tolerance:

Chain length tolerance ≤ +0.15% (ISO 606) prevents meshing impact/early failure.

Component Fit:

Pin-bushing clearance controls load distribution (excessive interference reduces fatigue strength).

Avoid selecting chains based solely on the tensile strength; also need consider fatigue limits and lubrication needs. Replace chains if elongation exceeds 3%.

Testing Methods & Standards

Static Tensile Test: Universal testing machine applies load until fracture; force-displacement curve recorded.

Dynamic Fatigue Test: Staircase method (ISO 15654) validates fatigue strength (≈2-month cycle).

Common Misconceptions Of Tensile Strength

Bigger Tensile Strength is Always Better

Oversized chains may not be optimal; proper sizing based on load requirements is essential.

Oversized chains may not be optimal; proper sizing based on load requirements is essential.

Operating at or near the Ultimate Tensile Strength (UTS) is unsafe; always adhere to the recommended Working Load Limit (WLL).

CTS® | Manufacturing Durable Roller Chains

High-performance Material

Chain Plate: 45Mn

Chain Pin: 20CrMnMo

Chain Bushing: 20Mn

Superior roller chain materials ensure a longer service life.

Nitro-Carburizing Compound Heat Treating

CTS uses automatic heat treatment, which is more efficient and accurate. During the carbonitriding heat treatment process, the addition of ammonia significantly enhances the roller chains' durability and resistance.

Wide-waist Link Plates

Increasing in width of the waist, wider-than-standard waist link plates greatly increase chain fatigue resistance and shock-load resistance.

Reliable Quality with Competitive Pricing

Customized Solutions for Your Needs

Fast Delivery and Global Support

Our roller chains will undergo rigorous testing and quality control, ensuring they meet performance standards.

Contact us today! Our team is eager to assist you in finding the perfect roller chain solutions for your business needs.

Appendix: Reference Table (ANSI Roller Chain & ISO Roller Chain)

| Roller Chain Size | Chain Pitch(mm) | Tensile Strength(kN) | Roller Chain Size | Chain Pitch(mm) | Tensile Strength(kN) |

| 12.700 | 18.6 | 12.700 | 19.4 | ||

| 15.875 | 31.3 | 15..875 | 27.5 | ||

| 19.050 | 43.2 | 19.050 | 32.2 | ||

25.400 | 74.3 | 25.400 | 77.1 | ||

31.750 | 107.6 | 31.750 | 112.8 |