What Are Roller Chains Made Of?

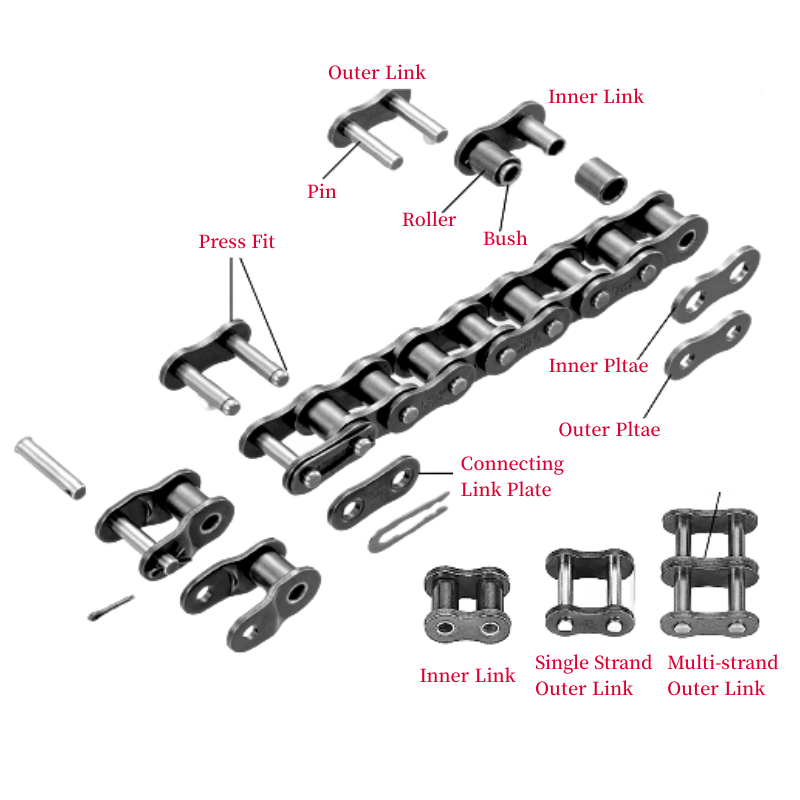

Components of Roller Chain

Chain Outer Plates: These form the outer side of the chain and hold the pins in place.

Chain Inner Plates: These components connect to the bushings and provide the chain with structural integrity.

Chain Pins: Serve as the pivot point between links.

Chain Bushings: Sit between the pins and rollers, allowing smooth rotation.

Chain Rollers: Roll over sprockets to reduce friction and wear.

Each of these components may be made from different materials or undergo different treatments depending on the application.

Materials Used in Roller Chains

Carbon Steel

Carbon steel is one of the most common materials used in roller chains. It offers a good balance between strength, durability, and cost.

Grades: Typically, low to medium carbon steels (such as Grade 30 to 70) are used.

Applications: General-purpose uses in industrial machines and agricultural equipment.

Alloy Steel

For high-performance or heavy-duty applications, alloy steel is used. It contains additional elements such as nickel, chromium, or molybdenum to improve strength and wear resistance.

• Grades: Often Grade 80 to 100.

• Applications: Lifting equipment, conveyors under heavy load, and automotive drives.

Stainless Steel

Stainless steel chains are ideal for environments where corrosion resistance is essential, such as food processing, marine, or medical equipment.

• Common Types: Stainless Steel 304 or 316.

• Features: Resistant to rust, chemicals, and moisture.

• Applications: Clean rooms, outdoor equipment, and wet environments.

Roller Chain Surface Treatment and Coating

The base material is often treated or coated to improve performance. Here are some common surface treatments:

Heat Treatment

Heat treating components like pins and plates can greatly improve tensile strength and fatigue resistance.

Shot Peening

This process involves bombarding parts with small steel balls to improve their surface durability and reduce the chance of fatigue failure.

Coatings

Zinc-plated or Galvanized: Offers basic rust protection.

Nickel-plated: Improves appearance and provides moderate corrosion resistance.

Zinc-flake Coating: Provides better corrosion resistance than traditional galvanizing.

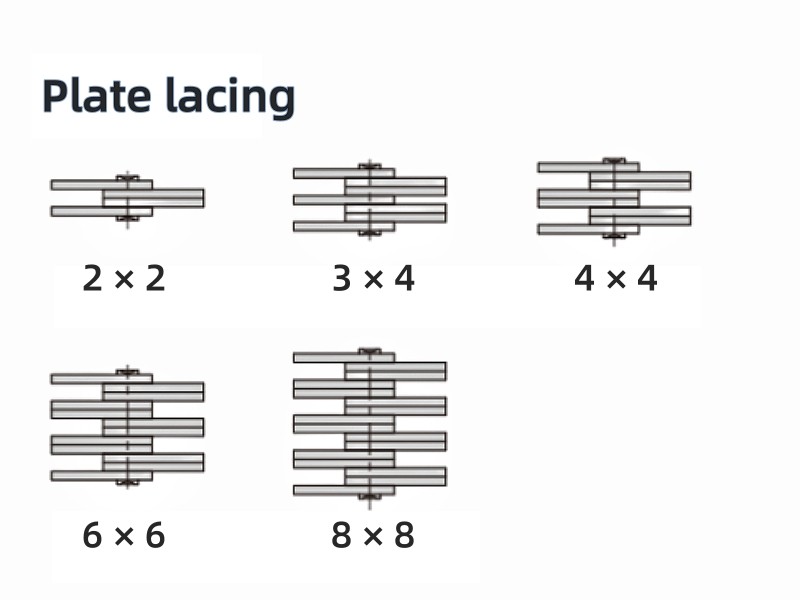

Common lacing types include 2×2, 2×3, 3×4, 4×4, 4×6, 6×6, and 8×8.

The first number = outer plates;

The second = inner plates.

Choosing the Right Material for Roller Chain

Load Requirements

Use alloy steel for high-load applications.

Corrosion Resistance

Choose stainless steel or coated chains for harsh environments.

Maintenance Access

Self-lubricating or O-ring chains are better for places where regular maintenance is difficult.

Cost

Carbon steel is usually the most budget-friendly option.

Roller Chain Size

CTS® | Professional Chain Manufacturer

As a professional roller chain manufacturer, our roller chains are made of high-performance material, through heat treatment with wide-waist link plates to provide high tensile strength.

High-performance Material

Chain Plate: 45Mn

Chain Pin: 20CrMnMo

Chain Bushing: 20Mn

Superior roller chain materials ensure a longer service life.

Nitro-Carburizing Compound Heat Treating

CTS uses automatic heat treatment, which is more efficient and accurate. During the carbonitriding heat treatment process, the addition of ammonia significantly enhances the roller chains' durability and resistance.

Wide-waist Link Plates

Increasing in width of the waist, wider-than-standard waist link plates greatly increase chain fatigue resistance and shock-load resistance.

As a professional chain supplier, we offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.