Sugar Mill Chain for Sugarcane Harvest

Sugarcane harvesting and processing put extreme demands on every piece of equipment in the mill, especially the chains. Whether in cane carriers, levellers, or bagasse conveyors, sugar mill chains must operate smoothly under heavy loads, sticky juice, and constant wash-down. Sugar mill chains play a vital role in conveying, crushing, and processing sugarcane in harsh environments.

What Is a Sugar Mill Chain?

Sugar mill chains are heavy-duty industrial chains used in the mechanical processing of sugarcane. These chains are engineered to perform in high-moisture, abrasive, and load-intensive conditions, typically found in sugar mills during the harvest and crushing seasons.

Key Applications in Sugar Mills

Cane carrier conveyors

Intermediate cane carriers

Bagasse handling systems

Cane levellers and feeders

Sugarcane Harvest Chain Type

In sugar cane processing, from strong welded chains in crushers to corrosion-resistant cast chains in bagasse production lines. At CTS ChinaTransmissions, we utilize high-performance materials, precision processing, and expert engineering support to manufacture and customize all of these chain types to meet your specific operational needs.

Steel Bushed Chain

Steel bushed chains are strong and long-lasting, ideal for sugar mills. They have steel bushings and pins for better wear resistance. These chains work well in slow, heavy-load conveyors, like cane carriers and intermediate carrier systems.

Cast Combination Chain

This chain combines cast iron inner links with steel sidebars or outer links. The cast iron provides superior corrosion resistance while steel adds tensile strength, making it ideal for wet or corrosive sections of the sugar mill.

Welded Steel Chain

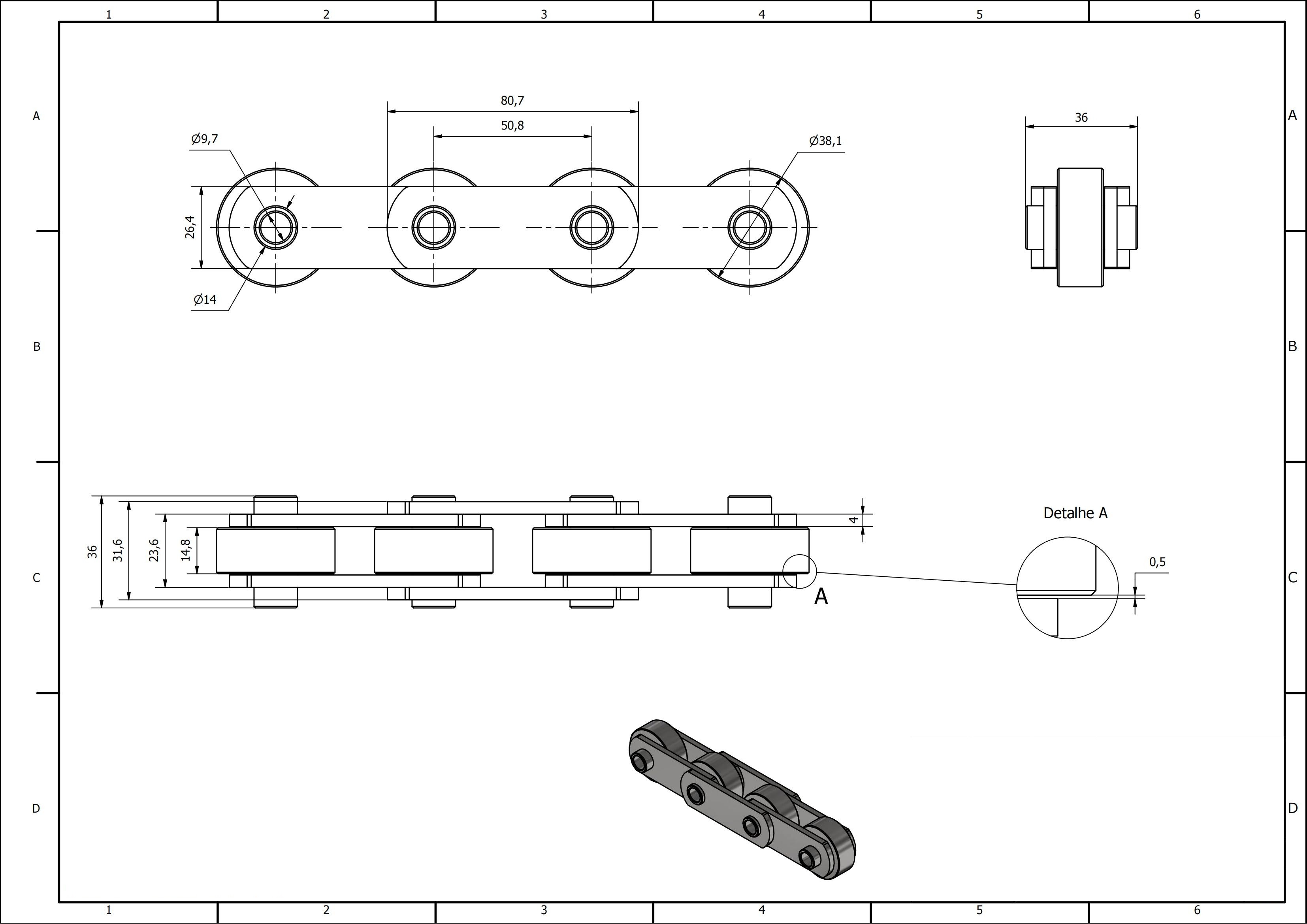

Welded steel chains are fabricated entirely from steel plates and pins, welded for maximum structural strength. They are commonly used in crushers and carrier systems. And there are chain attachments available for many applications.

Drop Forge Rivetless Chains

Known for its open design and easy maintenance, drop forged rivetless chains are ideal where frequent cleaning and reassembly are required. Their forged components allow for high strength without rivets, reducing the chance of jamming due to cane juice or sticky materials.

S-Type Bar Loop Chains

S-type barloop chains are specially built for use in Donnelly chute carriers and tight curved conveyors, where short center distances and steep inclines are common. They feature loop-style links for flexibility and shock absorption in high-speed or angled conveyors.

How CTS Supports Sugarcane Mill Chain Worldwide

What Sets Us Apart

✔ Professional manufacturing experience

✔ Strict quality control and ISO-certified production

✔ Engineering support for chain design and installation

Product Customization

Custom pitch and attachment options

Heat-treated materials for extended life

Tailored solutions for cane carriers and bagasse conveyors

CTS®-ChinaTransmissionS is a trusted supplier of industrial power transmission solutions, including custom sugar mill chains. Our chains are widely used in sugar mills across Southeast Asia, Latin America, and Africa. In addition, we also supply sprockets to match sugar mill chains.