Roller Chain Tensioners: Ensure Smooth Power Transmission

Roller Chain Tensioner

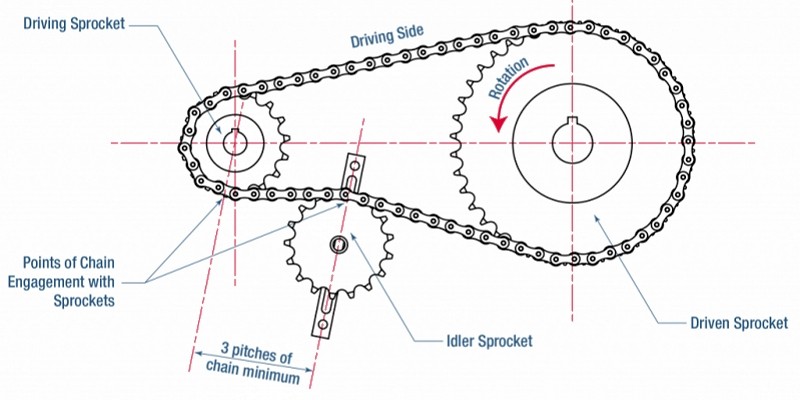

Roller chain tensioner is a mechanical device designed to maintain the correct tension in a roller chain drive system. By applying controlled pressure to the roller chain, the tensioner compensates for elongation and keeps the roller chain properly tensioned throughout its lifespan.

Why Proper Chain Tension Matters

Extended Service Life

Proper tension reduces wear on chains and sprockets, extending their operational lifespan.

Efficient Power Transmission

Optimal tension ensures smooth engagement between the chain and sprockets, leading to efficient torque transmission.

Reduced Vibration and Noise

Adequate tension minimizes chain sagging, reducing vibration and operational noise.

Prevention of Chain Failure

Correct tension prevents the chain from jumping or disengaging from the sprockets, avoiding potential equipment damage.

Types of Roller Chain Tensioners

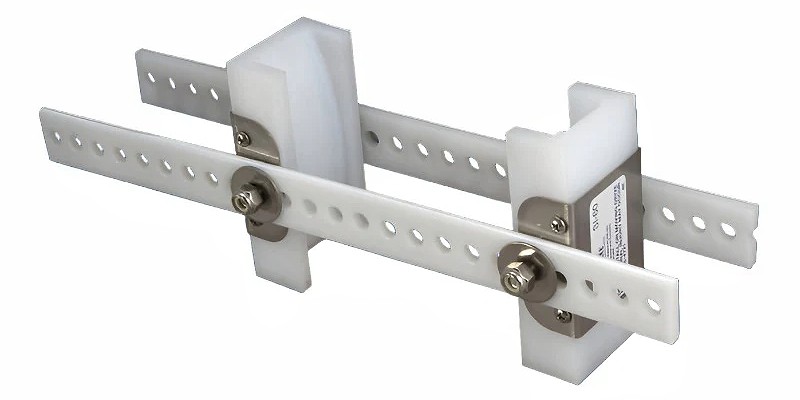

Floating Roller Chain Tensioners

These self-adjusting tensioners are mounted directly on the chain drive and use adjustable straps to apply constant tension. They are versatile, economical, and require minimal maintenance, making them suitable for applications in food processing, agriculture, and other industries.

Roll Ring Tensioners

Roll ring tensioners feature a toothed polymer ring placed between the chain strands. As the drive operates, the ring compresses, absorbing slack and dampening vibrations. They are easy to install, maintenance-free, and effective in applications requiring reversible operation.

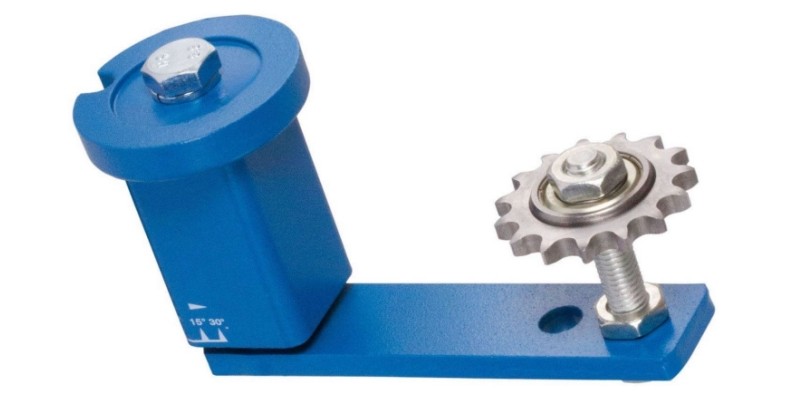

Arm Style Roller Chain Tensioner

Manual tensioners require operator intervention to adjust chain tension. They come in two main types: adjustable-arm and adjustable-screw. Adjustable-arm tensioners allow positioning the arm at various angles, while adjustable-screw tensioners use a screw mechanism for precise tension adjustments.

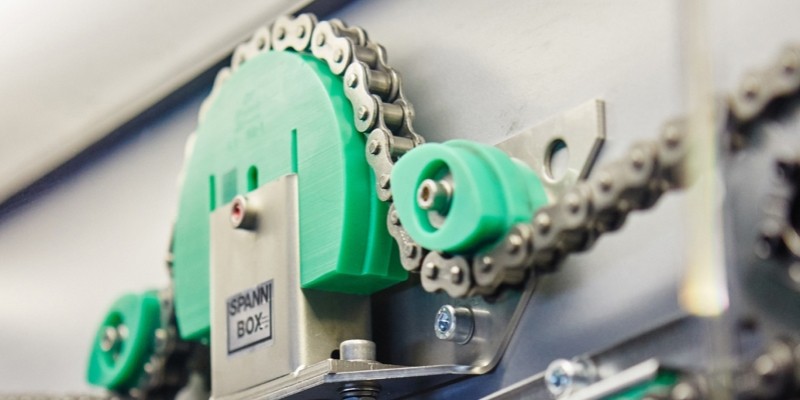

Spann-Box Tensioner

Spann-Box tensioners are designed for automatic chain drive tensioning in restricted installation spaces. They come in various sizes and materials, including UHMW profiles with stainless steel or plastic housings, and are suitable for different ANSI chain sizes.

How to Choose the Right Chain Tensioner

When selecting a roller chain tensioner, consider the system's load requirements, environmental conditions, and maintenance capabilities. Heavy-duty applications demand robust tensioners, while harsh environments—exposed to dust, moisture, or chemicals—necessitate corrosion-resistant materials. Additionally, choose a tensioner that aligns with your team's installation and maintenance proficiency, opting for user-friendly designs if resources are limited.

Common Mistakes to Avoid When Using Chain Tensioners

Over-tightening the Chain

Believe it or not, tighter isn't always better. Over-tightening can cause excessive wear and even snap chains.

Ignoring Regular Maintenance

Even the best tensioners need love. Skipping inspections invites trouble.

Using the Wrong Type of Tensioner

One size doesn't fit all. Make sure the tensioner matches your chain's size, load, and environment.

CTS® | Professional Chain Supplier

CTS®-ChinaTransmissionS is a professional roller chain supplier in the power transmission industry.

We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you have any questions about roller chains, please contact us.