Roller Chain Failures: Casuses and Solutions

Quick-Reference Roller Chain Failure Table

| Symptom | First Checkpoint | Next Step if Unresolved |

| Elongation(>2%) | Measure chain stretch | Inspect lubrication & contamination |

| Skipping | Check elongation & sprockets | Realign shafts |

| Noise/Vibration | Lube level & chain tension | Inspect rollers & plates |

Rust/Pitting | Environmental controls | Upgrade to corrosion-resistant chain |

Link/Pin Fracture | Shock-load protection | Use higher fatigue-rated chain material |

Roller Chain Failures Analysis

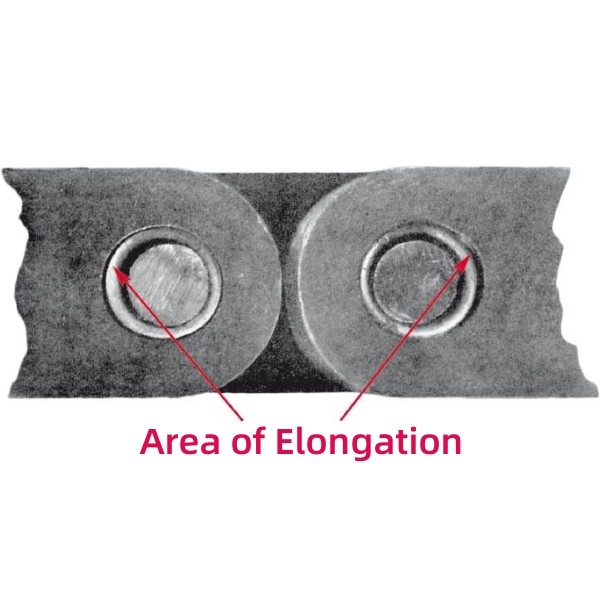

1) Roller Chain Elogation(Chain Stretch)

• Chain measures over 2% longer than nominal pitch

• Poor sprocket engagement, frequent skipping

Cause

1. Normal wear between the pin and bushing

2. Inadequate lubrication (high friction accelerates wear)

3. Contaminant ingress (abrasive dust or debris)

Solution

✔ Replace the chain at 2 % elongation

✔ Stock spare chains; swap as part of planned maintenance

✔ Switch to an oil-mist or centralized lubrication system

✔ Use oil with EP additives

✔ Install full-cover chain guards

✔ Clean and re-lubricate at more frequent intervals

2) Chain Skipping or Jumping

• Chain skips a tooth under load

• Intermittent power loss, lurching motion

Cause

1. Excessive chain elongation

2. Worn or hooked sprocket teeth

3. Misalignment between driver and follower sprockets

Solution

✔ Measure & replace the elongated chain

✔ Inspect sprockets; replace if the teeth profile is hooked or mushroomed

✔ Realign shafts within 0.1mm per meter using laser or dial-indicator tools

✔ Add adjustable motor mounts

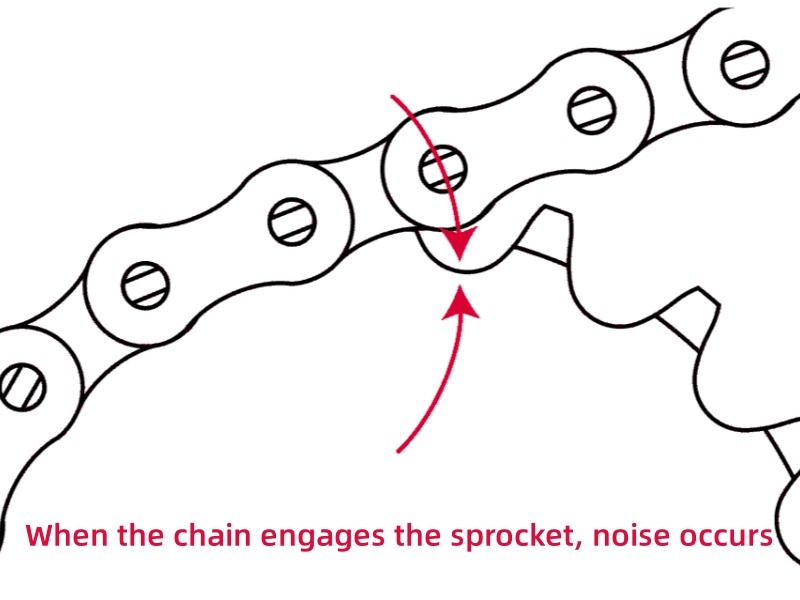

3) Abnormal Noise or Vibration

• Grinding, rattling, or metallic clicking

• Noticeable vibration at the chain drive

Cause

1. Lack of lubrication or wrong lubricant viscosity

2. Loose chain tension

3. Damage to rollers or link plates

Solution

✔ Verify lubricant viscosity matches operating temperature

✔ Increase application frequency

✔ Set tension so chain droop is 2–3 % of span length

✔ Install automatic tensioners in long spans

✔ Inspect for flat spots or cracks; replace damaged chain links

4) Corrosion & Surface Pitting

• Rust discoloration on plates and rollers

• "Pitted" metal surfaces are visible

Cause

1. Exposure to moisture, acids, or alkalis

2. Infrequent cleaning—trapped water/chemicals degrade metal

Solution

✔ Switch to stainless-steel or nickel-plated chain

✔ Improve drainage and humidity control

✔ Implement wash-down procedure with rust-inhibitor rinse

✔ Dry thoroughly, then re-lubricate

5) Link or Pin Breakage

• Sudden chain fracture at a single link

• Complete drive shutdown

Cause

1. Shock loading (jams, sudden torque spikes)

2. Fatigue cracking from cyclic bending at the pin-plate interface

3. Manufacturing defect or material inclusion

Solution

✔ Add shock absorbers or torque-limiting couplings upstream of the chain drive

✔ Use a chain with case-hardened pins and a higher fatigue rating.

✔ Avoid operating above rated load.

✔ Source chain from ISO- or ANSI-certified suppliers.

✔ Inspect the new chain before installation.

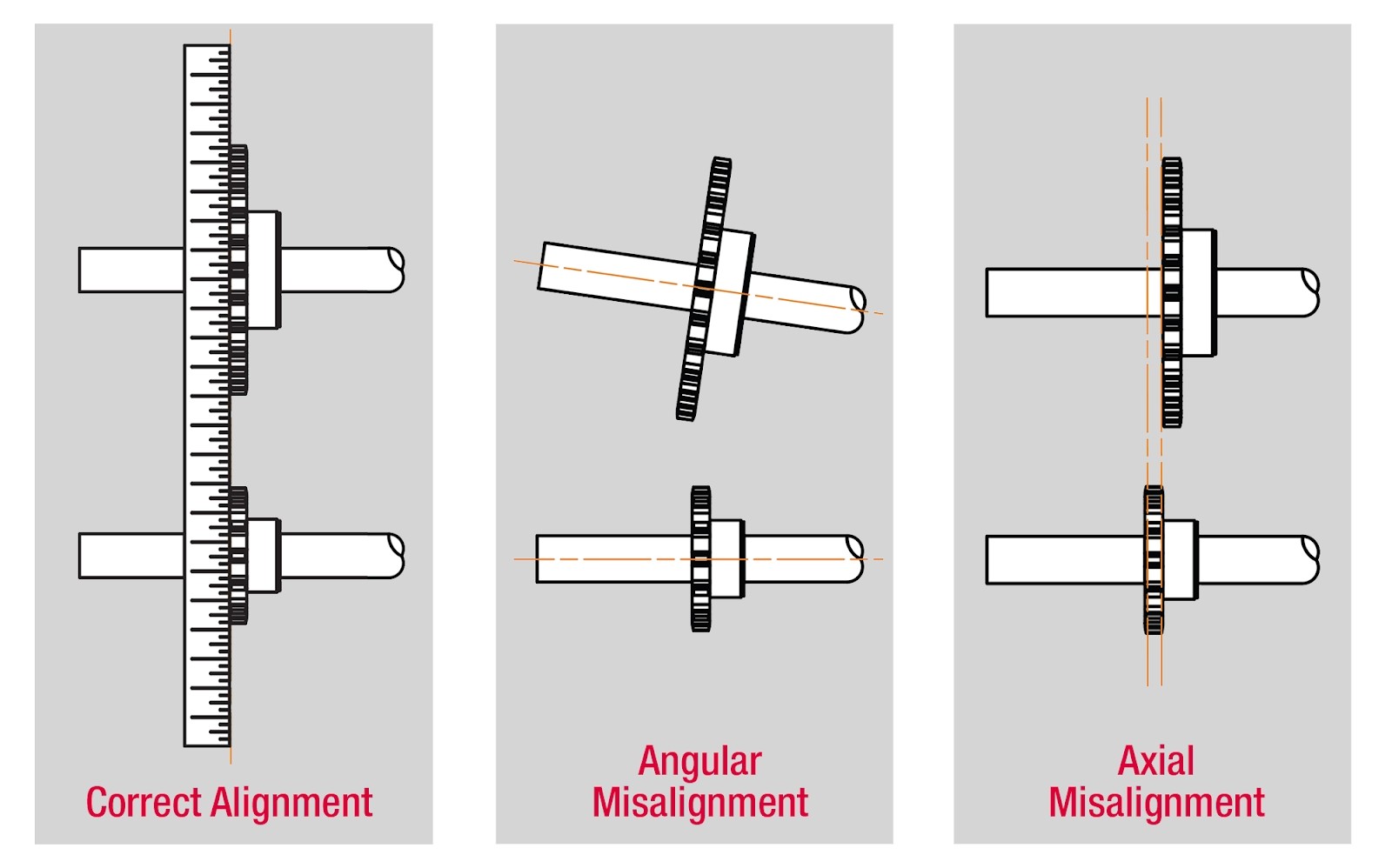

6) Excessive Wear on One Side of the Chain

• One side of the link plates or rollers shows deeper wear

• Chain binds or rubs against guides

Cause

1. Sprocket misalignment or shaft deflection

2. Side-loading from poorly designed guides or sprockets

Solution

✔ Check & correct alignment; use precision machining for bearing seats

✔ Redesign guides for full-face support.

✔ Ensure sprocket faces are square to the chain path.

Real Case Study

Situation: A high-speed food-packaging line was experiencing chain breakage every 2–3 weeks.

Analysis: Microscopic pitting had combined with inadequate lubrication and rapid-cycle loading to initiate fatigue cracks.

Solution: Switched to stainless-steel chain with a food-grade oil-mist system, increased sprocket alignment precision, and added a shock-absorbing tensioner.

Result: Mean time between failures rose to over six months, cutting downtime by 90 %.

CTS® | Professional Chain Manufacturer

CTS®-ChinaTransmissionS is a professional roller chain supplier with over 15 years in the power transmission industry.

As a professional roller chain supplier, our experienced technical team always learns the latest manufacturing technology. We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you have any questions about roller chains, please contact us.