It Is Time to Replace Your Roller Chain!

If you're not sure when to replace the chain, when you notice any of these signs below, it's time to replace new roller chains.

Signs Your Roller Chain Needs Replacing

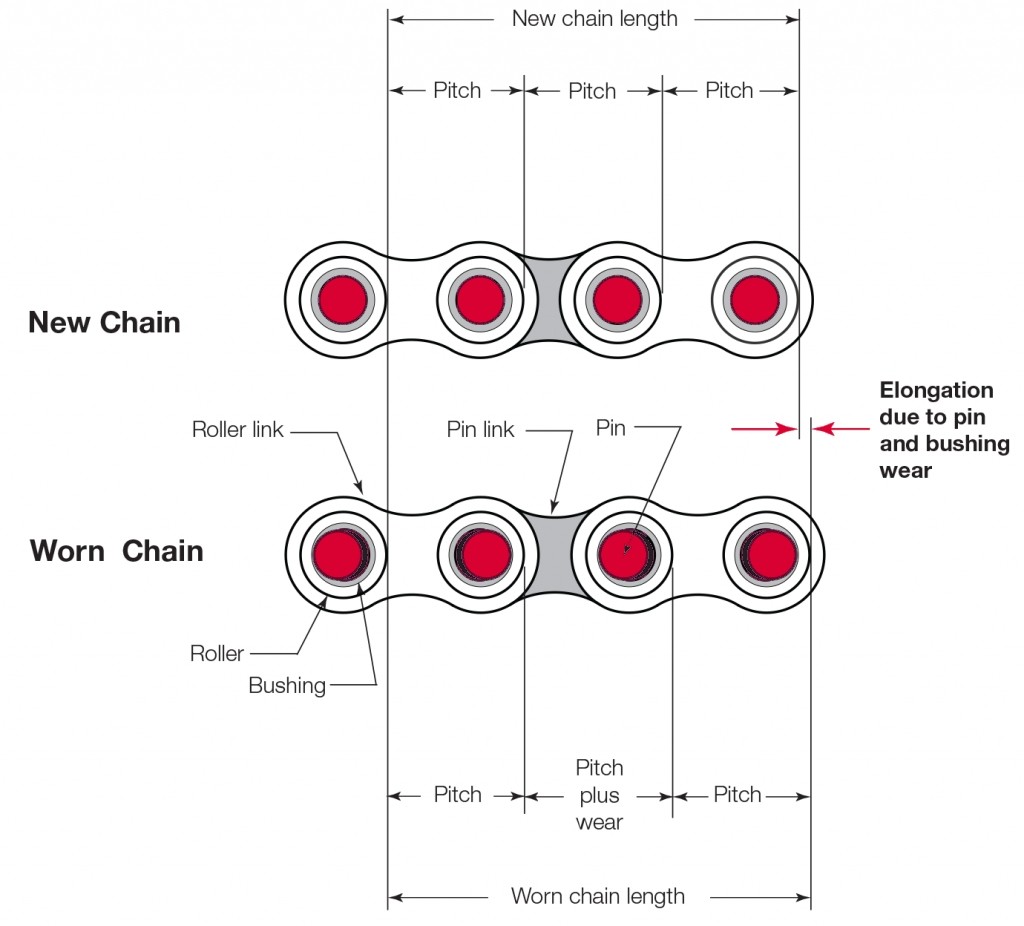

1) Roller Chain Elongation(Chain Stretch)

Over time, roller chains grow longer because the pins and bushings wear down. You can measure this by comparing the current chain length to its original length. If the roller chain is stretched by more than about 1% to 3%, it should be replaced to avoid slipping off the sprockets or damaging other parts.

2) Corrosion or Deep Rust

Roller chains exposed to moisture, salt, or chemicals can form rust spots and small pits. Surface rust might be cleaned off, but if you see deep pitting or cracking, the chain can jam or break unexpectedly. Replace it before internal corrosion causes failure.

3) Excessive Noise or Vibration

Normally, roller chain should run quietly and smoothly. If you hear grinding, squeaking, or notice shaking when the chain moves, that often means parts are worn or misaligned. Replacing the chain (and checking sprocket alignment) usually fixes these problems.

4) Visible Wear on Rollers, Bushings, or Pins

Look closely at each roller, bushing, and pin. If the rollers are thinner than they should be, cracked, or if the bushings and pins look loose or flattened, that means the chain is worn out and needs replacement.

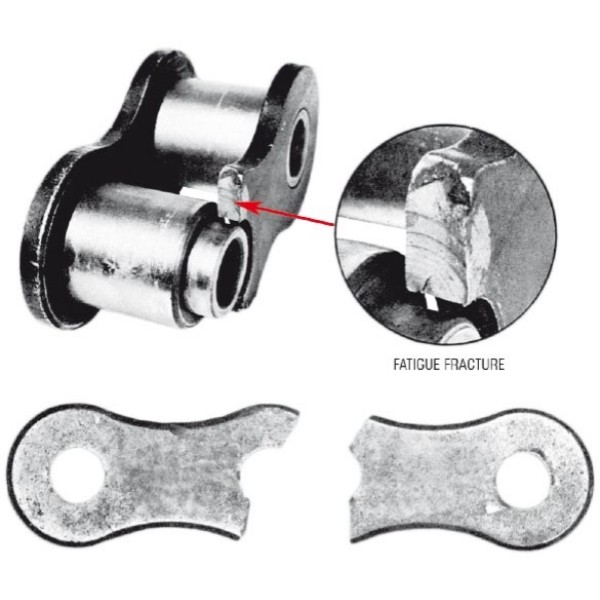

5) Frequent Breaks or Stiff "Binding" Links

If the chain keeps breaking or you find stiff links that don't bend smoothly, it may be overloaded or damaged. This can happen if the chain has seen heavy shocks or poor lubrication. Check that the chain size and strength match your equipment; if broken links or tight spots keep appearing, replace the whole chain for safety.

6) Loss of Proper Tension (Chain Slack)

A correctly adjusted chain will have just a bit of give. If you have to tighten it more and more, but it still feels loose, that means the chain has stretched past its safe limit. A loose chain can skip or fall off under load. When you see too much slack, swap in a new chain.

7) Worn Sprocket Teeth

When a chain is worn, it wears the sprocket teeth into a hooked or pointed shape. If you notice that the sprocket teeth are sharp, hooked, or uneven, the chain has likely been wearing on them. It’s best to replace both the chain and the sprockets together to keep everything fitting and running smoothly.

Methods to Make Your Roller Chains Last Longer

Proper Lubrication

Apply the right lubricant regularly, ensure full coverage of pins, bushings, and rollers to reduce friction and wear.

Proper Installation

Fit new chains by using correct installation tools (e.g., master links, rivet tools) to avoid damage.

Match Chain to Application

Choose a chain grade (e.g., heavy-duty or stainless steel) suited to speed, load, and environment. Replace worn sprockets when fitting a new chain to prevent premature wear.

Correct Tension

Maintain a slack of about 1–3% of the center‐to‐center distance. Avoid over-tightening (which stresses links) or over-loosening (which causes whipping and skipping).

Accurate Alignment

Align driving and driven sprockets within 1–2 mm of parallelism. Misalignment increases side loads on chain links, accelerating wear.

Protect from Corrosion

Use rust-inhibiting spray or corrosion-resistant chains in humid or chemical environments. Store spare chains in a dry, clean area.

Match Chain to Application

Choose a chain grade (e.g., heavy-duty or stainless steel) suited to speed, load, and environment. Replace worn sprockets when fitting a new chain to prevent premature wear.

Regular Inspection & Cleaning

Check for stretch, wear, corrosion, and stiff links every few weeks (or per operating hours). Remove dirt, grit, and old lubricant before re-lubricating; contaminants act like abrasive particles.

CTS® | Professional Chain Manufacturer

CTS®-ChinaTransmissionS is a professional roller chain supplier with over 15 years in the power transmission industry.

As a professional roller chain supplier, our experienced technical team always learns the latest manufacturing technology. We offer various industrial chain options: roller chains, conveyor chains, stainless steel chains, heavy-duty roller chains, double-pitch roller chains, roller chain attachments, etc.

If you have any questions about roller chains, please contact us.