Elevator Conveyor chain——robust chain for vertical conveying

What Is Bucket Elevator Conveyor Chain?

A bucket elevator conveyor chain is a specially designed chain used in vertical lifting systems to move bulk materials efficiently. These chains are equipped with buckets attached at regular intervals, allowing for smooth transportation of materials vertically. They are most commonly seen in industries like cement production, grain handling, fertilizer plants, mining, and more.

Unlike horizontal conveyor systems, bucket elevators need components that can endure vertical loads, dynamic impact, and harsh environmental conditions.

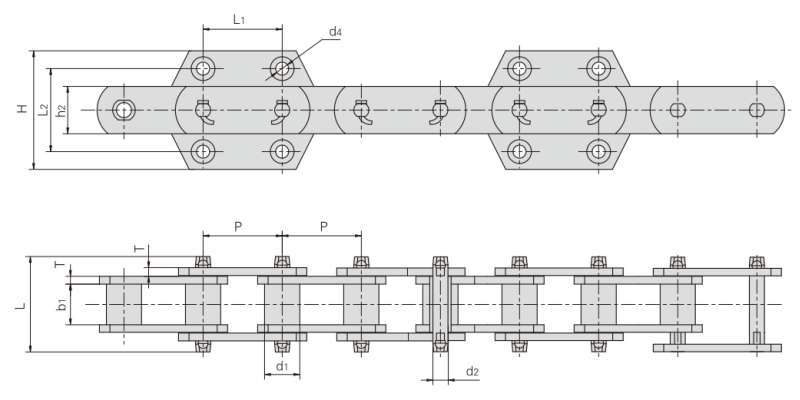

Bucket Elevator Chains Size

How Do Bucket Elevator Chains Work?

The working principle of a bucket elevator chain involves four key actions:

Loading: Buckets collect bulk material from a loading station.

Lifting: Bucket elevator chain and buckets are driven by a sprocket system to move vertically.

Discharging: Buckets empty their contents at the top, often via centrifugal or gravity discharge.

Returning: The empty buckets descend back to the bottom for refilling.

Bucket elevator conveyor chains must withstand not only the weight of the buckets and material but also wear, corrosion, and fatigue from continuous cycling.

About Double Pitch Roller Chains

A typical bucket elevator chain system includes:

• Roller chain links: Provide motion and bear loads.

• Bushings and pins: Connect links and allow pivot motion.

• Attachments: Welded or riveted parts that support the buckets.

• Buckets: Often made from steel or plastic, designed to scoop and carry materials.

• Sprockets: Drive wheels that engage with the chain to move it upward.

Material selection of elevator chains

| Carbon Steel | Common and cost-effective |

| Alloy Steel | Offers higher strength and wear resistance |

| Stainless Steel | Provides corrosion resistance for chemical or wet environments |

Heat-treated components | Enhance fatigue and impact resistance |

Surface treatments such as carburizing, nitriding, or galvanizing may be applied for added protection.

Common Challenges and Failure Modes

Chain Elongation

Due to wear between pins and bushings

Sprocket Wear

Worn sprocket teeth reduce engagement and chain life

Fatigue Failure

Caused by repeated stress cycles, especially if the load is not balanced

Corrosion and Rust

Especially in a chemical or wet environment

Bucket Separation

Improper attachment design or excessive vibration can lead to bucket detachment

CTS | Professional Roller Chain Manufacturer

CTS-ChinaTransmissionS, as a trusted roller chain manufacturer, we're here to help you choose the best chain for your application. Also, we manufacture sprockets to work with bucket elevator conveyor chains. Need custom-engineered bucket elevator chains or expert selection support? Contact us for professional guidance and reliable solutions.