How Chain and Sprocket Support Lumber Industry

Lumber Industry Chain and Sprocket

We understand the demands of the lumber processing industry. With decades of expertise in chains and sprockets, we deliver reliable solutions to keep your operations running smoothly. Minimize downtime and maximize productivity – trust CTS to keep your operations on track.

✔ Durable Chain & Sprocket

✔ High-performance

✔ Custom service

Types of Chains Used in the Lumber Industry

Roller chains are used in conveyor systems throughout the mill. Their smooth operation and ability to handle both high speed and load make them a common choice for material transfer.

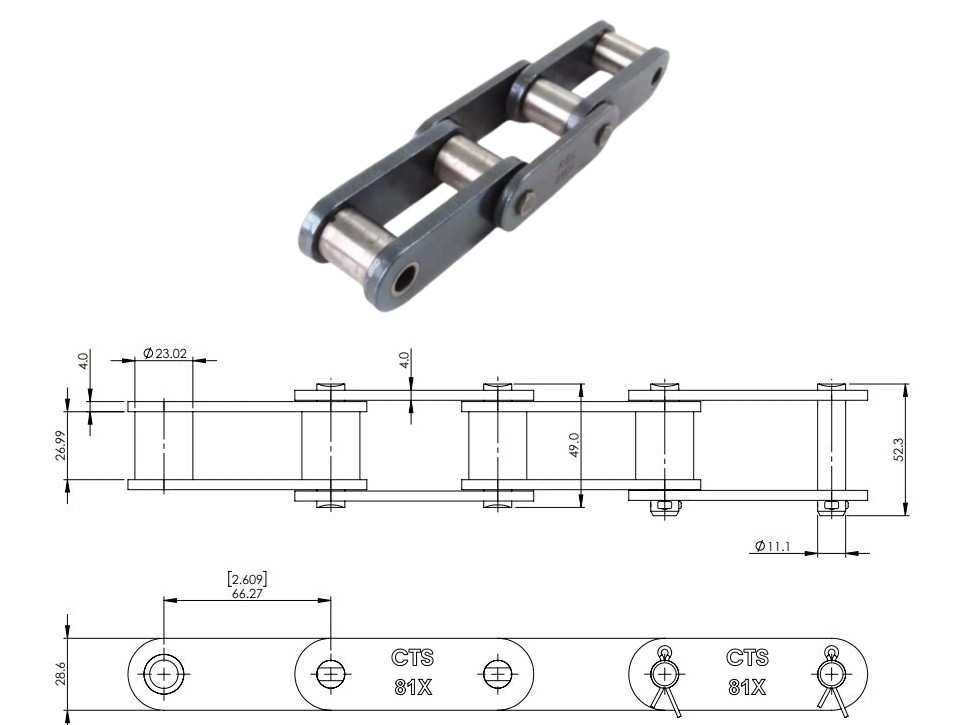

The 81X conveyor chain with a standard pitch of 2.609 inches and a straight sidebar design, it's built to handle high loads while maintaining stability. Whether moving timber in a sawmill or grain on a farm, 81X chain gets the job done.

Sharp Top Chains

Equipped with sharp points or lugs, sharp top chains are ideal for feeding logs and boards through cutting and trimming machines. They grip the material firmly and move it with precision.

Drag Chains

Drag chains are built for handling loose materials like bark, chips, and sawdust. Their open design and reinforced structure allow them to operate reliably in debris-heavy conditions.

Welded steel chains offer extreme strength and wear resistance. They are often used in the heaviest-duty systems, such as log infeed conveyors or heavy-duty stackers.

Sprockets for Lumber Mill Applications

Sprockets must match the pitch and roller size of lumber conveyor chains. A poor fit can cause premature wear or chain derailment.

For the sprocket bore size and keyway, we can customize for you to ensure secure mounting and precise alignment in larger industrial machinery.

Key Applications in Lumber Mills

Chains and sprockets are used in almost every stage of the lumber production process. Key applications include:

Log Decks: Chains lift and feed logs onto conveyors for initial processing.

Debarkers and Chippers: High-strength chains withstand impact and debris during log stripping.

Sorting and Grading Lines: Chains move cut boards through scanners and sorters with precision.

Stackers and Trimmers: Chains lift and position boards for stacking or further cutting.

Waste Conveyors: Drag chains move bark, sawdust, and chips to disposal or recycling stations.

Each of these applications places different demands on chain strength, wear resistance, and alignment. Choosing the right lumber industry chain and sprocket is important, you can contact our technicians for help.

Custom Chain and Sprocket Solutions

While many standard chains and sprockets are suitable for lumber applications, some situations require customization:

Unusual dimensions or pitches

Special lugs, attachments, or teeth designs

Non-standard bore sizes or shaft connections

Before manufacturing, our technicians will make the chain and sprocket drawing for your checking, ensuring fit your application.

Need help finding the right chain or sprocket for your lumber mill? Contact our team for expert guidance and tailored solutions.

Choose CTS® Lumber Conveyor Chain & Sprocket

From log decks to stackers, the lumber conveyor chain and sprocket power every stage of production. Parting with CTS-ChinaTransmissionS -- the reliable suppliers, lumber mills can improve uptime, lower long-term costs, and operate more safely and effectively.

If you have any questions about industrial transmission chains, please contact us for help.