Precision Machining for Industrial Transmission Products

The precision machining process we are proud of is the core to ensure the excellent performance of the sprocket chain, through the use of state-of-the-art highly automated equipment and continuous technological innovation.

Highly Automated Manufacturing

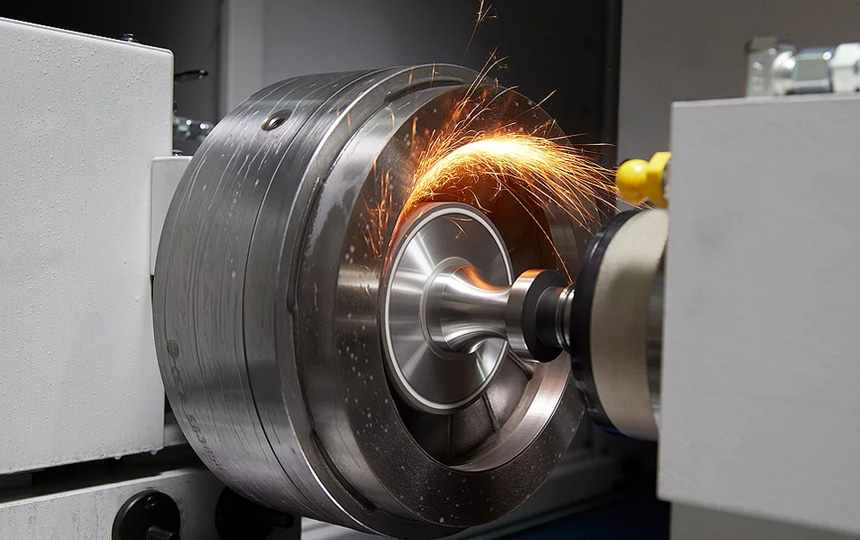

Turning

Turning is a manufacturing process that involves rotating a workpiece and cutting material with a tool. In the manufacture of industrial sprockets and gears, the turning process plays a vital role in the accuracy of the shape and the smoothness of the surface.

High Precision: Turning can be used to precisely cut the shape of industrial sprockets and gears to ensure that their geometry meets design requirements. This is critical to drivetrain stability and efficiency.

Ensure Surface Flatness: The turning process can provide a surface with higher flatness, which helps to reduce the friction and wear of industrial sprockets and gears during movement.

Through advanced turning equipment and technology, we are able to achieve micron-level precision, ensuring that the shape and surface flatness of each industrial sprocket and gear meet the highest standards. This precise turning process is the basis for high-quality sprocket chains.

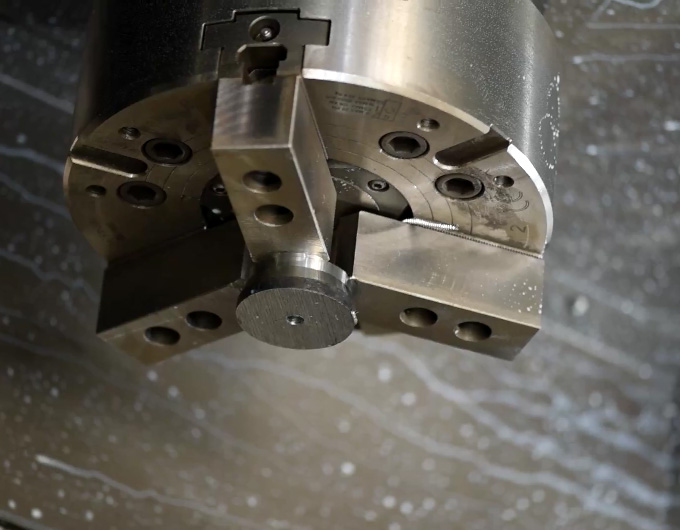

Milling

Milling is a manufacturing process in which a tool is moved over a workpiece to remove material to form the desired shape. In the production of sprocket chains, the milling process is used to create specific contours and grooves.

Precise Formation of Contours and Grooves: Milling allows us to form the various contours and grooves on the sprocket chain according to the design requirements, ensuring that it will fit accurately with other components.

Surface Finish: Milling can provide a relatively smooth surface, which helps reduce friction in the movement of the sprocket chain and prolongs its service life.

CTS uses high-precision milling equipment and advanced tool technology to ensure that every contour and groove of the sprocket chain meets the design requirements. This precision milling process is integral to achieving a high-quality sprocket chain.

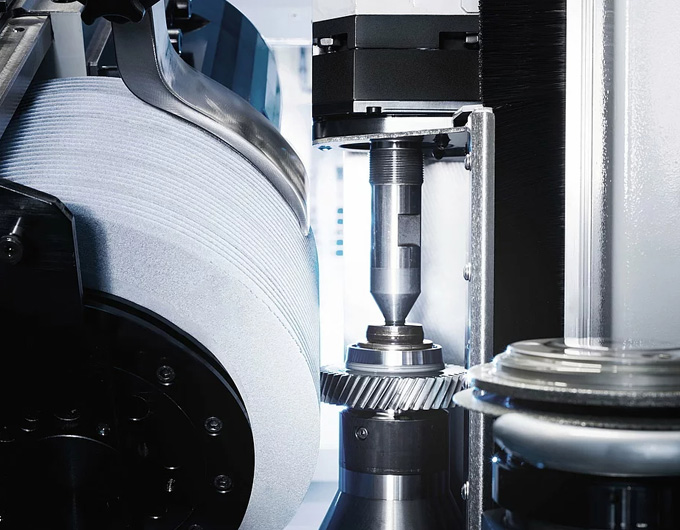

Grinding

Grinding is a machining process that uses abrasive particles to cut a workpiece to form a precise shape. In the manufacture of sprocket chains, grinding processes are often used to improve dimensional accuracy and surface smoothness.

Dimensional Accuracy: Grinding enables extremely high dimensional accuracy, ensuring that the dimensions of the sprocket chain meet the most demanding engineering requirements.

Surface Smoothness: Grinding can produce a very smooth surface, reduce the friction of the sprocket chain during movement, and improve transmission efficiency.

CTS uses advanced CNC grinders and high-efficiency grinding tools to ensure that each component of the sprocket chain can achieve the expected dimensional accuracy and surface quality. The meticulous grinding process is an important step in ensuring high-quality sprocket chain manufacturing.

Application of technological innovation