Chain and Sprocket Matching Guide

Chain sprockets mesh with the chains to move or rotate other components. They are commonly used together in machines like conveyors, agricultural equipment, and industrial systems.

If the chain and sprocket are improperly matched, the chain may slip or jump, sprocket teeth may wear out faster. A correct match ensures smoother performance, enhances durability, reduces noise, and maintains efficient power transfer for reliable operation.

How to Select the Right Sprocket for Your Chain

Identify the Chain Size

Check the chain's size code, such as ANSI 40, 50, or 60. This code tells you the pitch (distance between pins), roller diameter, and plate width.

Choose a Sprocket with the Same Standard

The sprocket must match the same standard as the chain (e.g., ANSI chain should match an ANSI sprocket). Don't mix ANSI with ISO or other types—they have different dimensions.

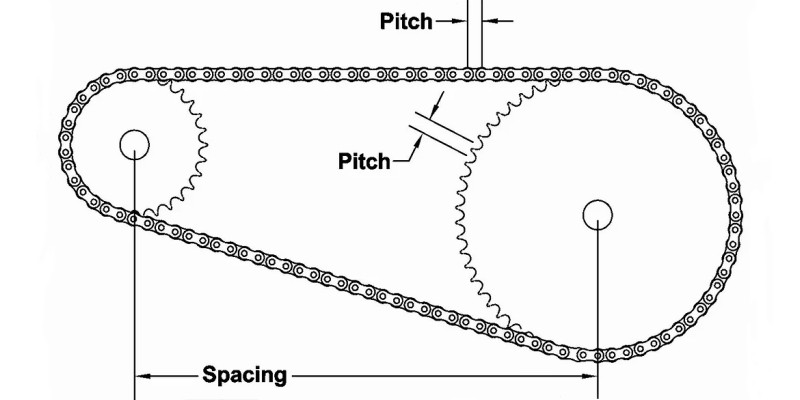

Match the Pitch Exactly

The chain sprocket teeth must have the same pitch as the chain to ensure smooth engagement.

Check Number of Teeth

Choose the correct number of teeth on the sprocket based on your speed and torque requirements. Fewer teeth give more torque but faster wear; more teeth give smoother operation and longer life.

Select the Right Bore Size

Make sure the sprocket's center hole (bore) matches your shaft size. Choose between finished bore, taper bore, or pilot bore types, depending on your application.

Confirm Tooth Width and Roller Fit

The sprocket teeth must fit well between the inner plates of the chain and match the roller diameter.

Material and Type

Choose the right material based on your working environment. Steel is common for heavy-duty use, while stainless steel or plastic is better for food-grade or corrosive conditions.

Tips for Ensuring a Perfect Match

Always use chains and sprockets from the same standard.

Check manufacturer catalogs for matching specs.

Use calipers to measure pitch and roller diameter if unsure.

Replace both components at the same time for better performance.

Standard Chain and Sprocket Types

Problems Caused by Mismatched Components

Premature Wear: Uneven wear on sprocket teeth and chain pins.

Noise and Vibration: Improper fit leads to rough engagement.

Chain Jumping or Slipping: Dangerous and can cause machine damage.

Reduced Efficiency: Power loss due to chain and sprocket poor meshing.

Shorter Service Life: More frequent roller chain and sprocket replacements are needed.

CTS® | Professional Chain and Sprocket Supplier

CTS®-ChinaTransmissionS is a professional roller chain supplier with over 14 years in the power transmission industry. We offer a wide range of industrial chain and sprocket options: roller chains, conveyor chains, stainless steel roller chains, chain sprocket, etc.

If you have any questions about roller chains, please contact us.